Plastics Industry

Discover how you can apply Simco-ION products in your plastics manufacturing business

Applications for the Plastic Industry

Simco-ION offers solutions to control static electricity in the plastics industry, processes like static free winding on Blown film production or Cast film extruders. Using an electrostatic charge to optimise In Mould Labeling (IML) processes on injection moulding machines. Controlling static electricity will prevent electrostatic shocks to operators during roll changes on Slitting machines and prevent dust attraction before Flexoprinting or other printing on plastics processes. Also process disruption on Sheeters or Slitters or during bagmaking on bag making machines can be prevented.

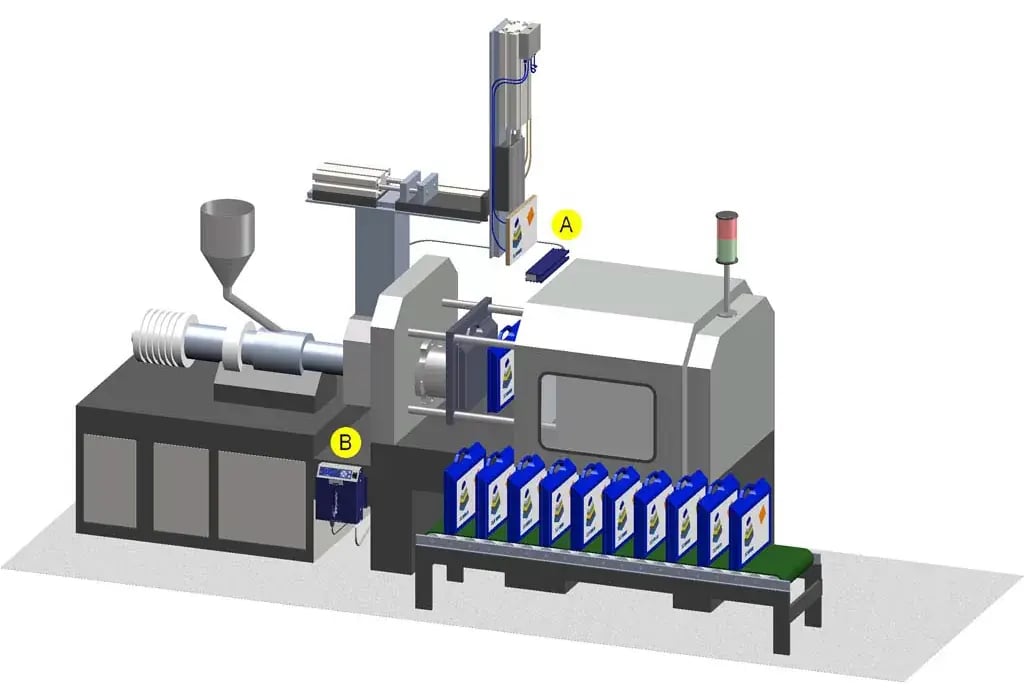

In Mould Labeling, also referred to as IML, with the help of static electricity is becoming the new standard in injection moulding, thermoforming and blow moulding industry. Instead of conventional methods like decorating by printing directly or placing an adhesive label onto the product, the decoration is achieved with a pre-printed plastic label. The pre-printed label is positioned into the injection mould and kept in place by an electrostatic charge. This way the label will be moulded together with the product shape and comes out as a finished, fully recyclable product.

What is In Mould Labeling (IML)

Whether you are an end-user or a robotics manufacturer, Simco-ION can assist you with advice and knowledge in creating the perfect In Mould Labeling solution. It is essential when starting a new IML project to make the right decisions to create a competitive product.

Outside the mould the robot picks-up a single, pre-printed label to transport (high-speed) and place it into the mould cavity (single or multiple), where it sticks due to the electrostatic bond between the label and the metal mould wall (ground potential). Therefore the label will not slip or change position in the mould during the moulding process and a perfect In Mould Labeling result can be achieved with an optimal cycle-time.

Static electricity and IML

We have years of experience with the In Mould Labeling process and In Mould Labeling equipment and therefore developed solutions for both metallic and non-metallic printed labels:

- Several charging techniques (pinning, direct & simplified IML)

- High voltage charging IML generators; 100-240V and special end-of-arm 24V IML Charge Master Micro Easy (CMME)

- IML electrodes; high voltage bars and the special IML-spider

- IML electrode materials (semi-conductive foam and special 2-component potting IML Easycore)

- IML high voltage cables (extra flexible for cable chain)

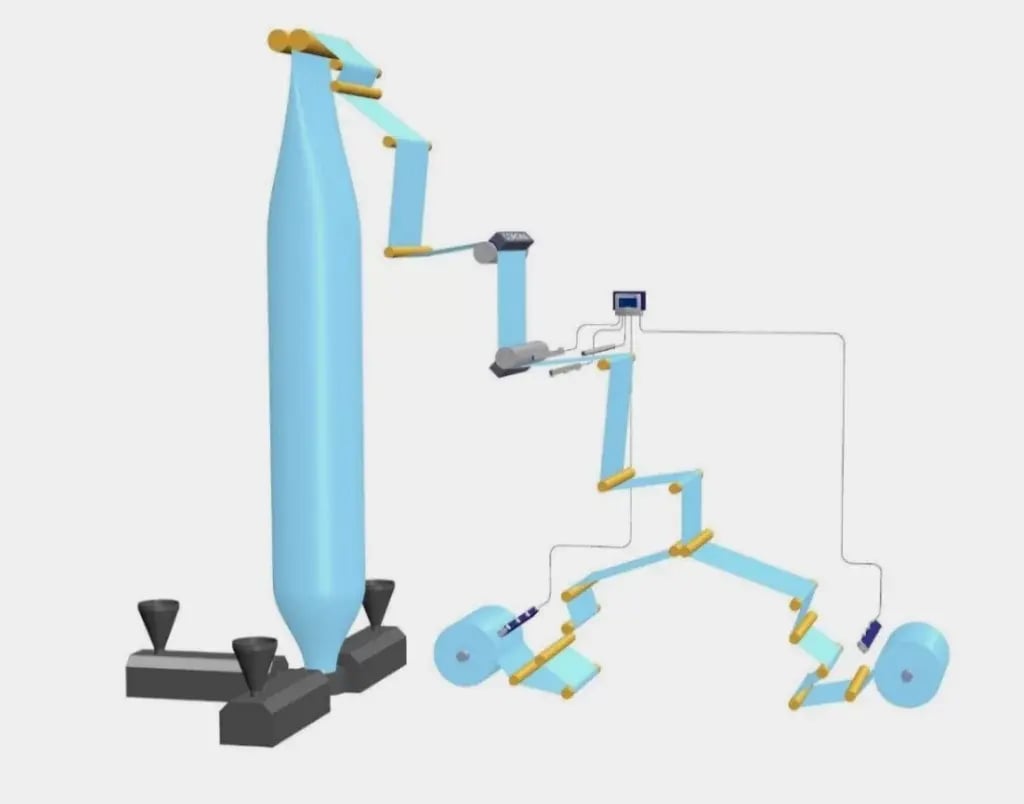

Blown Film

Prevent static shocks on blown film lines

Blown film extrusion is used to produce packaging film, much of which is multi-layered. This is done to improve mechanical, transport, and thermal properties, as required by the food or medical industry. The height of the “bubble” of the blown film line is needed to cool down the material, before the nip rolls / top rolls. You can recognise static charges by experiencing shocks or seeing sparks as a discharging effect.

After the material passes the nip (top) rollers on the blown film line it is generating static electricity and building up high static charges. This due to friction by passing several rollers and temperature fluctuation because the material is cooling down. If the material passes a corona treater, a massive static charge is created on the material. Here an extra section of static eliminators, preferably with inline static measuring (Close Loop Feedback), is recommended.

On the final winder(s) long range static elimination bars are installed to neutralise the material during winding. Applying the ThunderION IQ static eliminator will guarantee that the complete material is neutralised. Starting as small diameter to end as large diameter rolls.

This will prevent dust-attraction, telescoping of the end roll and unpleasant static shocks to the operator. When winding double layer (tube) material, static elimination is essential to be able to open the material after unwinding. Sometimes discharging before winding is needed to reach a low static charge on the end roll. Normally 24V static eliminators are used for discharging here.

The pollution of the static eliminators is a critical issue. To avoid a drop in efficiency this level can constantly be monitored by the Manager IQ Easy or the Smart SLC.

If the efficiency drops below a pre-defined level, the operator/PLC receives a warning. Maintenance will be indicated on the polluted static bars.

For more intelligence, the IQ Easy System can be directly connected to the Blown film line via a Fieldbus connection. This is how all essential information is collected regarding the efficiency and required maintenance of the static equipment. Also the level of static charge on the material is collected and logged.

This all results in high quality, competitive production of blown film.

Slitting and Rewinding

Slitting/Rewinding is a process to cut different type of jumbo roll’s with various material-width to narrower sizes at (very) high speed. This technique is suitable for several materials like paper, plastic film, flexible packaging, fabric or textile. The web is unwound and run through the slitter/rewinder, passing adjustable cutting knives, before being rewound on one or more shafts to form narrower rolls.

Slitting/rewinding your foil is usual business nowadays, because of the high speed and the number of rollers (friction), static electricity can create major problems.

Immediately after the slitting operation and before the winder, 24V Performax (IQ) Easy Speed anti static bars will be installed. These static elimination bars will neutralise the static electricity generated during the previous unwinding and slitting process and will prevent:

- New generated static during winding

- Attraction of (cutting) dust

- Employees getting shocks from static discharges

- Telescoping effect on your slitted rolls

If a predefined low static level on the end-product is required, an in-line measurement system can offer this solution. To achieve this, a IQ Easy System can offer real-time managing and monitoring options with a full controlled Closed Loop Feedback system (CLFB).

This system monitors and controls all connected static eliminators and can be directly connected to the machine PLC via Fieldbus connection. This provides all information about efficiency and required maintenance of the static eliminators, as well as the static charge including alarms. In-line measuring and datalogging of electrostatic charge levels can be used in quality reporting.

These options contribute to increase static control of the process, operator safety and product quality, which all together results in high quality competitive slitting and rewinding.

Bagmaking

Static electricity on bagmaking machinery: a problem and a help

Bag making machines come in various configurations based on the type of bags produced by the machine. The bag making machine produces a bag by unwinding a roll of plastic film through a series of operations like (heat) sealing, cutting, slitting & stacking. Typical products are garbage bags, T-shirt bags, shopping bags and bags with a draw-tape.

Bagmaking machinery creates a lot of static electricity. Because of the construction of the machinery, the rollers create friction between the roller material and the plastic foil that is passing. This friction creates electrostatic charges on the surface of the material (bags).

These electrostatic charges can cause the machine run poorly, making bad stacks so decreasing production yields and increasing rejects. These kind of problems are recognizable on most types of bagmaking machinery such as Bags-on-Roll (interleaf) and Bag-on-Bag (for instance with a wicketer). These machines can be found in multiple industries like general packaging, food, beverage and medical.

Static elimination

To neutralise electrostatic charges on bagmaking machines, Simco-ION offers a complete program of static eliminating products. Often applied are the AC static eliminators MEB, MaxION or the ½” Super Service bars (made of Teflon so applicable at the sealing unit: heat resistant). Additionally 24V static eliminators are used such as the Performax IQ Easy (speed), VicinION or ThunderION IQ. These are both long range discharging bars, so eliminating the electrostatic charges responsible for stacking problems, especially needed on wicketer machinery.

Generating static

Less well known is the fact that static electricity is used to support a variety of processes, especially on bag making machines. It is applied for charging a roll, in example of garbage bags, to prevent air inclusion, further disturbances in the process and keep the roll compact. Also sticking material to a metal roller, without air inclusion, optimizes the cooling process.

Charging of the last bag of a roll, fixes the end of the roll and facilitates the following packing much easier into an outer carton. In many processes static charge is applied to improve production control by charging the bottom and/or side fold of the material or to assist during transport and stacking in the machine.

The combination of our CM5 and HDR charging bar is the perfect solution for generating static in a safe and controlled way to improve your process.

Perforation detection

The controlled generation of sparks is also used to detect perforations (pinholes), for quality inspection purposes.

Besides the fact that this is an interesting solution for non-contact inspection of product quality, there is also the possibility to count the number of perforations (also for biodegradable bags).

This production technique is made possible by Simco-ION high voltage generators, that are especially designed for this applications. With a high voltage static generator like the Simco CM5 generator or a Simco 24V Perfomaster the spark can be controlled and converted to a signal that is passed on the machine PLC. This data informs the PLC, so operators knows if a product has a defect, if it is in the right position or the number of products which have been produced.

These Simco-ION charging and discharging techniques result in high quality, competitive bagmaking!

Used devices:

Cast Extrusion

A charging applicator on each edge of the film on the cooling roll applies a static charge to the extruded film when it comes into contact with the cooling roll. The static charge effectively prevents neck-in of the film.

Used devices:

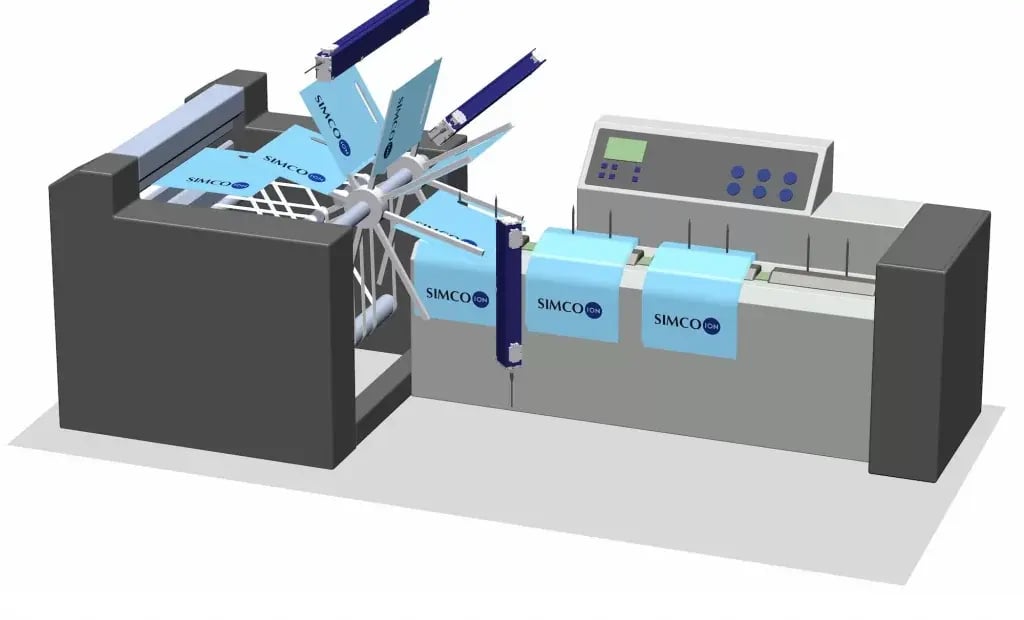

Sheeting

An ionisation bar installed above and immediately after the sheets directs the ionisation onto the sheets. Static charges are eliminated during sheeting. This allows neutralised sheets to be stacked correctly without jamming.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Bennie Bel, Technical Sales

“Even small charges can cause sheets to stick, dust to cling, or shocks to hit operators. Proper static control solves all three challenges at once.”