Style Guide

The perfect template to dial in your theme settings.

Static Charging

Static Charging

With Simco-ION products

Click on the buttons above to jump straight to the associated paragraph

High-voltage generators and charging electrodes or charging bars from Simco-Ion

High voltage electrostatic generators, like the Simco CM5 charging generator, create a controlled static charge up to 60kV on a non-conductive material that will allow a temporary adhesion between 2 surfaces with charges of opposite polarity. A high DC voltage (up to 60kV) can be safely produced and is carried to the emitters of an generator bar or electrode, where it is connected to an array of suitably designed emitter pins to generate a “corona”. A strong, ion-saturated electrical field around the single polarity high voltage points forces the material to a reference earth clinging the different surfaces together.

How does electrostatic charging work and how does a generator look like?

A static charging system consist of a high voltage generator and an electrode. The high voltage generator supplies the high voltage needed to create a static charge. This can vary from 3 to 60 kVolts. The charging electrode comes in different shapes to enable an optimum result for each specific application. Currently Simco-Ion high-voltage generators are used for the production of the facemask with types FFP1, FFP2 and FFP3 that are used against the spread of the Corona-virus. More on the physics side of electrostatic charging can be found here.

Different type of generators

Choosing the right generator is mostly based on the space that you have available and the voltage (power) that is needed to get the job done. We offer:

- Small footprint generators (20kV) or dedicated generators for IML applications (end of arm tool)

- Medium power electrostatic generators up to 20kV

- High power static generators from 30kV HV Generators up to 60kV-HV Generators

High voltage electrostatic generators, like the CM5 charging generator, create a controlled static charge up to 60kV on a non-conductive material that will allow a temporary adhesion between 2 surfaces/materials with charges of opposite polarity. A high DC voltage (up to 60kV) is generated safely and carried by a high-voltage cable to the emitters of a charging applicator, charging electrode or charging bar to generate a “corona”. A strong, ion-saturated electrical field around the single polarity high voltage points, forces the material to a reference earth, clinging the different surfaces together.

Choosing the right generator is mostly based on the space that you have available and the voltage (power) that is needed to get the job done. We offer the following generators:

- CM Lite Small footprint charging generators (20kV)

- CMM Easy IML Dedicated charging generators for IML applications ( end of arm tool)

- CM Lite power charging generators up to 20kV

- CM5 charging generators with 30kV and 60kV

Charging applicators are the extensions of the static charging generators to reach the material. With the charging applicator, a high-voltage field can be applied to the material. Charging Applicators come in different shapes. All have pins where the Corona effect is generated. There are single point applicators like pinner-electrodes, and there are bar-shaped charging applicators. These can be mounted inside machines for continuous charging, or momentarily charging of material that is processed inside the machine.

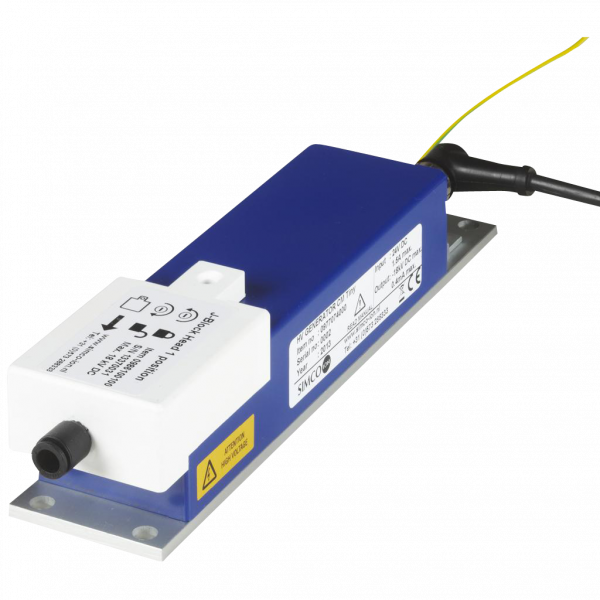

CM Tiny

The CM Tiny is the smallest industrial charging high voltage static generator for applications like static bonding, static cling or static used to glue materials together. The generator only needs 24V DC voltage. The housing is compact, robust and only weighs 500 grams which makes it perfect for small machines and applications with moving parts like pick and place handling systems. It can easily withstand the high G-forces occurring during the process.

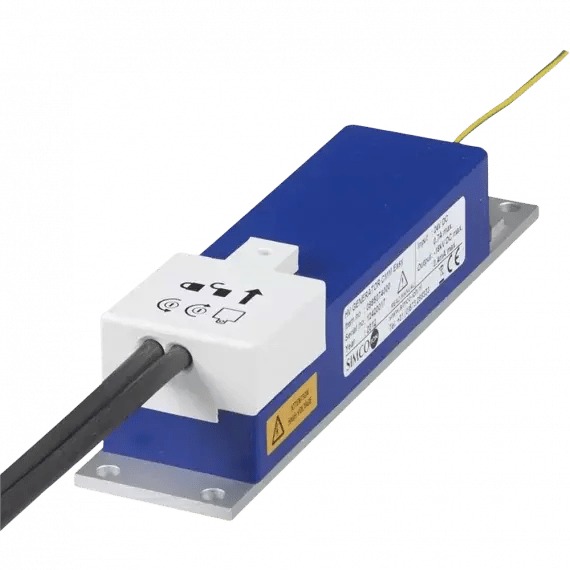

CM Lite

The CM Lite is a mid-sized industrial charging high voltage static generator for applications like static bonding, static cling or static used to glue materials together. The 20kV generator only needs a 220V AC voltage power supply. The housing is compact and robust and weighs 5,2 kilograms. The high voltage with an adjustable output voltage (both positive and negative) of 0 – 20 kV (with a maximum current of 0,7 mA) is shown on the digital display. A remote control option is available and a warning light shows whether the system is overloaded or if spark-over occurred.

CM5-30

CM5 is backwards compatible with the ECM30/60 and ECM DI30/60. A quick set-up menu is provided to set-up the generator to function as an ECM30/60. The menu is available in English, German, French and Italian.

The new function “current control” will enable you to set a constant current vs a constant voltage. This will provide more stable charging and will compensate contamination and emitter pin wear automatically.

CM5-60

CM5 is backwards compatible with the ECM30/60 and the ECM DI30/60. A quick set-up menu is provided to set up the generator to function as an ECM30/60. The Menu is available in English, German, French and Italian.

CMM (IQ) Easy

The CMM Easy is a small profile footprint charging generator, specially designed for IML applications. The housing is compact, robust and only weighs 500 grams, which makes it perfect for end of arm mounting in IML pick and placehandling systems. It can easily withstand the high G-forces occurring during the IML process.

Simco-Ion Europe offers a variety of charging bars and electrodes

Simco-Ion Europe offers a variety of charging bars and electrodes, depending on the specific applications and conditions. These bars are connected to a Static Charging Generator. The bars have the length of a normal static eliminator and can be placed inside machines. The length usually depends on the size of the material that needs to be charged. A strong, ion-saturated electrical field around the line of high voltage points of the charging bars can force material to glue together or to charge. The material is charged by the ions that are created and directed by the charging bar. Surfaces with different polarity glue or cling together temporarily. There are various methods of temporarily charging materials electrostatically, using a Simco-Ion Chargemaster Static Generator.

Simco-Ion offers two different types of charging electrodes that both can be connected to a Static Charging Generator.

- HDC Static Generator Electrode for universal solutions.

- HDR Static Generator Electrode for high-speed solutions.

HDC

A static charging system consists of a high voltage generator and an electrode or applicator and cabling. The high voltage generator supplies the high voltage needed to create a static charge. This can vary from 3 to 60 kVolt. The charging electrode or charging applicator comes in different shapes to enable an optimum result for each specific application. Size and shape differ to make optimum solutions for each situation.

HDR

The HDR charging bar suits high velocity applications. Each individual point being fitted with a resistor, so the chance of spark-over is strongly reduced.

Simco-Ion Europe offers a variety of charging bars and electrodes

Simco-Ion Europe offers a variety of static charging bars and static charging electrodes, depending on the specific applications and conditions. These bars are connected to a specific DC high-voltage Charging Generator. A strong, ion-saturated electrical field around the single polarity high voltage points forces the material to a reference earth. The material is charged by the ions. Being attracted by different polarities a force is created. The force can make materials or surfaces temporarily cling together when in close proximity. There are various methods of temporarily charging materials electrostatically, using a Simco-Ion Charging Generator and Static Charging electrodes. The combination of a type of Charging Generator and Charging applicator is called a Static charging system.

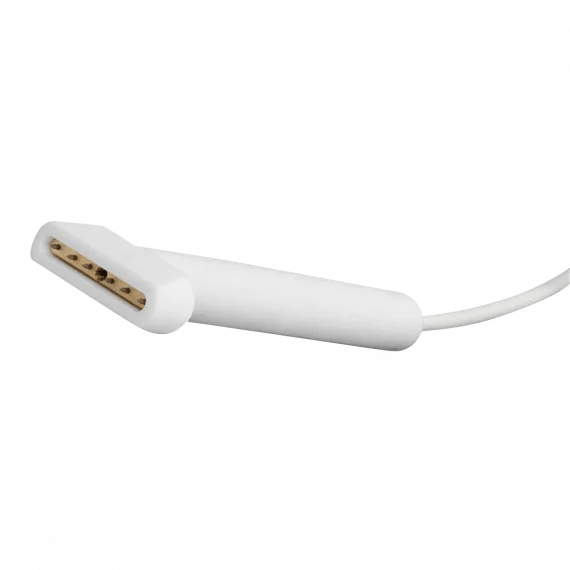

Different types of electrodes are:

- Pinner Claw for edge(directional) charging for spot-surface-charging and pinning

- Pinner 5 Point (focus round) for edge pinning in cast-film extrusion process

- Linear 6 Point (focus inline) small surface and edge pinning solutions.

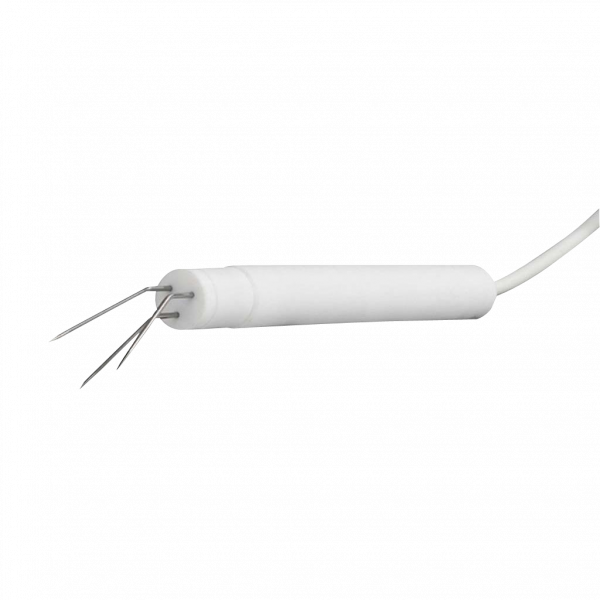

Pinner Claw

Simco-Ion Europe offers various electrodes, including the 5 Point, Linear 6 Point and the Pinner Claw, specifically for spotcharging small surfaces. These electrodes are also ideal for edge charging in cast-film extrusion processes. The material applied permits high temperature use. The electrodes are resistor-protected to avoid sparkover. The points are replaceable.

Pinner 5 Point

Simco-Ion Europe offers various electrodes, including the 5 Point, Linear 6 Point and thePinner Claw, specifically for spotcharging small surfaces. These electrodes are also ideal for edge charging in cast-film extrusion processes. The material applied permits high temperature use. The electrodes are resistor-protected to avoid sparkover. The points are replaceable.

Linear 6 Point

Simco-Ion Europe offers various electrodes, including the 5 Point, Linear 6 Point and the Pinner Claw, specifically for spotcharging small surfaces. These electrodes are also ideal for edge charging in cast-film extrusion processes. The material applied permits high temperature use. The electrodes are resistor-protected to avoid sparkover. The points are replaceable.

Both In-Mould Labeling (IML) and perforation detection use controlled electrical or electrostatic processes in production. IML fuses pre-printed labels into molded products, while high-voltage sparks detect holes or leaks in delicate materials without contact. These techniques rely on precise charge control to achieve reliable results.

Learn more on our dedicated page:

Freek Adolfsen, Territory Manager

“Controlled static charging can make your operations more efficient, and we guide you step by step to implement it in the best way for your business.”

Typography

You have the ability to have different typography settings for your website and landing pages which is what you see below. You can also control your blog posts typography seperately in the theme settings.

Heading 1

Heading 2

Heading 3

Heading 4

Heading 5

Heading 6

Morbi ultricies, this is a text link nibh quis tincidunt scelerisque, magna purus malesuada erat, feugiat semper urna lectus at sapien. Maecenas ornare, metus ut mattis vehicula, nulla nulla efficitur lacus, vitae congue nisi nibh eget massa. Sed nec pharetra mauris, ac volutpat metus. Praesent sed enim mollis, tincidunt orci sit amet, mattis risus.

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

In sit amet massa sed dolor tempor mattis id et tellus.

Icons

You can set a global default color for icons and will also have control in each module to select a specifc color if needed.

CTAs & Standard Buttons

You can set up various button styles to create a visual hierarchy. Pro-top: Make the Primary button pop the most.

Modal Popup

Modals pop-ups are features of various modules. You can give them global style.

Modal Headline

Donec sed pretium mauris. Suspendisse aliquam ornare quam, eleifend sagittis mauris interdum eget. Maecenas placerat mattis velit, in egestas erat vulputate vel. Morbi at nisl justo. Praesent quis erat risus.

Praesent varius quam quis ultricies consequat. Aenean ullamcorper commodo consectetur. Vivamus ex sapien, ullamcorper id ullamcorper in, eleifend in quam. Curabitur ac metus convallis, scelerisque libero in, vulputate justo. Mauris erat ex, commodo vitae ipsum et, vestibulum porttitor odio.

Forms

Create a form that has input fields, dropdowns, checkboxes, and everything. Then style it here.