Textiles Industry

Discover how you can apply Simco-ION products in your textile manufacturing business

Applications for the textiles industry

Simco-ION offers solutions to control static electricity in the textile industry like balloon forming or even yarn breaking in Creel processes. Removing static at the folding arm section can optimise Stenter stacking operations and eliminate electrostatic shocks to operators.

Warping, beaming and carding processes in the textile industry can all be influenced by static charges.

Synthetic Fibres

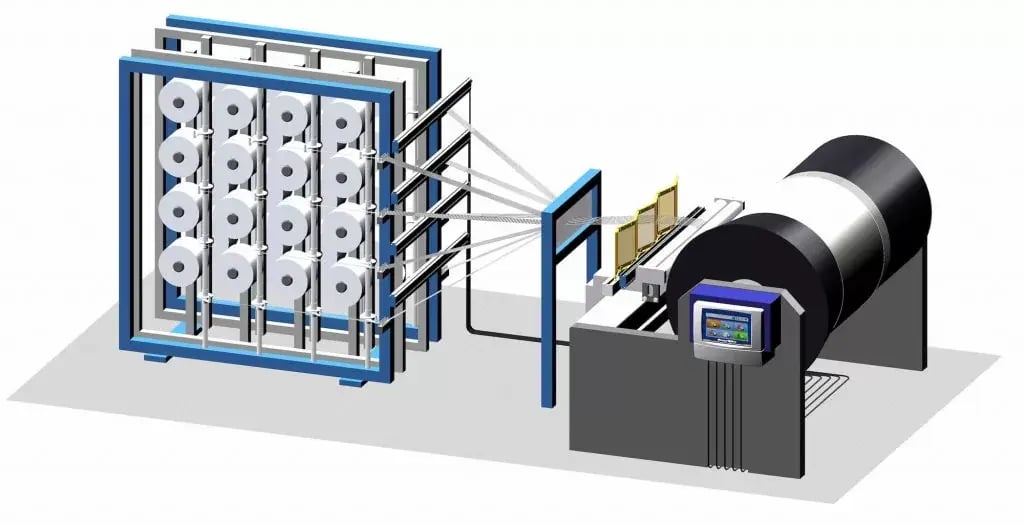

Synthetic, textile or plastic fibers are applied for a wide variety of products. This process includes the production and transport of long strings of material. A good example in the automotive industry are car tires, which are made of extruded rubber strings which are processed over special creel machines.

Due to a strong electrostatic charge plastic threads, textiles or even plastic hoses can repel, attract or inflate each other during the production process and possibly even adhere to machine parts. This can cause major problems when laying down textiles, neatly winding threads and hoses or generally during the further production process.

With warper creels or beam machines it becomes clearly noticeable that the filaments are electrostatic charged during unwinding. The result is a very unclean winding pattern, where the filaments tend to stick to parts of the machine. The electrostatic charge increases even more when passing through the creel.

At Simco-ION we also see this charging of the nonwoven wires in the production of car tires, which has similar effects as in the warp creel / beam machine. When the steel wires incorporated in tires are replaced by plastic wires, the wires become highly charged, which can lead to strong electrical discharges (i.e.sparks) in the further production process.

The filaments exiting the extrusion nozzle repel each other because they are electrostatically charged. This makes further processing (stretching, twisting or winding) more difficult.

By sensibly installing ionisation bars such as the Performax IQ Easy in the correct positions, these problems can be completely eliminated, even at very high material speeds.

In combination with the Simco-ION IQ Easy System, all connected ionisation devices can be monitored for efficiency and contamination. If you are experiencing similar problems, please do not hesitate to contact us.

Statically charged filter material

Statically charged filter material for better filtration of contaminants and particles.

Simco-ION offers electrostatic generators up to 60kV for the electrostatic charging of non-woven filter materials to achieve better filtration results by attracting and binding contaminants to the filter material.

Examples:

- Filter material for industrial use (for dust particles and vapour/mist filtration).

- Filter material for medical use (for face masks/caps/lab coats/coveralls)

Manufacturers of non-woven filter materials and producers of end products in this industry use Simco-ION high-voltage generators to charge the filter material. The use of electrostatic charging by means of high-voltage generators serves two purposes in this application:

- Charging the filter material to achieve better filtration results by attracting/binding contaminants to the material at the end user's site.

- Binding (aligning) multiple layers and materials together to achieve higher production speeds and thus higher machine performance.

For this application the CM5-30 high voltage charging generator, in combination with the HDR charging bar is a proven solution. With out Manager IQ or Smart SLC you can even have Closed-Loop Feedback Charging. The use of mentioned charging equipment increases the output from the machine and the filtration quality from the product so results in high quality competitive filter production.

Stenters

Electrostatic charges arise during the production, compression and preparation of textile webs. Static electricity causes the fabric to stick to machine frames, slowing down the machine. In addition, employees can receive electric shocks. On the finishing machine, the swivel arm cannot properly move the fabric into the end position due to attraction or repulsion between the textile surfaces. Ionisation bars prevent all problems related to static electricity and ensure that machines run smoothly.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Maik Zimmer, Sales Agent

“Clinging fibers and fabric misalignment are often caused by static. Effective control keeps production flowing and maintains high-quality standards.”