Packaging Industry

Discover how you can apply Simco-ION products in your packaging manufacturing business

Applications for the Packaging Industry

Simco-ION offers solutions to control static electricity in the packaging industry. Processes on shrink-wrap-machines or like preventing bad seals due to product fine attraction in Form Fill and Seal machines or Vacuum Form Fill machines or rejects in Blow moulding processes due to static charges on the parison. Removing static electricity in labelling processes will ensure correct placement and will prevent production stops in Sleeve- Shrink operations. Static solutions can also be found in horizontal Flow Wrap machines and Palletizers.

Shrink Sleeve Machine

Controlling static electricity on sleeve and shrinking machinery

A Sleeve/shrink labeller is a high-speed machine designed to apply shrink sleeve labels to a variety of bottles/containers. The shrink sleeve labeller can speed up to 800 products per minute with sleeves of printed thermal shrink film, after which the sleeves are shrunk to adhere to the bottles/containers. The machines are reliable, simple to use, flexible and they have an efficiency of almost 100%.

Printed shrink sleeves for decorating plastic (PET, PVC, PE) or glass bottles, offer an effective medium for advertising purposes and additional protection. The flat film is unwound and runs through a buffer-stack and is then pulled over a mandrel to form a tube. The sleeve is cut to size by knives in the cutting unit. The sleeve is then pushed down over the container and shrunk to fit the container contour in a heat tunnel.

The sleeve applicator machines are designed for full body and partial labeling.

Static electricity may cause the film to stick to the mandrel or, once cut, the sleeve is not properly positioned on the container. Anti static bars or static eliminators are placed at the indicated position to assure a correct functioning of the machine.

The Simco-Ion VicinION is an static elimination bar designed to neutralize electrostatically charged surfaces. This bar is the smallest sized 24V static eliminator on the market. The static eliminator is equipped with an integrated high-voltage power supply, Tungsten emitters and a status LED and is supplied with a 24V DC power supply via an M8 connector.

The VicinION is optimally used between a distance of 5 and 75 mm. The VicinION is available in effective lengths from 224 mm, in increments of 17,25 mm. Simco-Ion can help you solving any specific static problems resulting in high quality competitive packaging production including your sleeving process.

Used devices:

Pallet Wrapping

Static free high speed (in-line) pallet wrapping

Manually placing boxes on pallets and wrapping them can be time consuming and expensive. For this reason this process is often completely automated. Automated pallet wrapping lines come in a wide variety and always have one thing in common: problems with static electricity on the stretch and/or the top foil.

Stretch wrapping machines are used to wrap stretch film around a loaded pallet. Stretch pallet wrapping is widely used in general, food, chemical and electronic industry. A highly stretchable plastic film, commonly made from Linear Low-Density PolyEthylene (LLDPE), is wrapped around items. The elastic recovery keeps the products tightly bound. Stretch film is used to wrap products on pallets and secure them to each other and to the pallet during transport and storing.

After palletising, a top-foil dispenser can apply a protective sheet over the products to protect them from environmental influences such as humidity and dust. Neutralising static charges directly after unwinding can prevent the protective film from “clinging” and not fully covering the products.

During wrapping of the pallet with a stretch-foil, static charges can create shocks (discharges) to operators, electronic parts or optical sensors and cause dust attraction to the foil. An ultra-compact VicinION 24V static eliminator, mounted on the rotary arm, can neutralise the static charge after unwinding of this stretch film.

Prevent Air Inclusion

Static charge can be used to bond 2 materials together to prevent air entrapment

The Problem

Static charge can be used to bond 2 materials together to prevent air entrapment. Applications that benefit from this technique are:

- During bagmaking, parts of the bag are held together to prevent air inclusion during finishing.

- A roll of bags or film will be much tighter without air inclusion.

- Sticking material to a cooling roller without air inclusion optimises the cooling process.

The Solution

The materials that need to be bonded have to pass a charging electrode. Opposite to the charging electrode a ground reference is positioned, e.g. an idle roller. A static charge can be applied ranging from 3 kV to 120 kV depending on the material thickness, speed and adhesion force required.

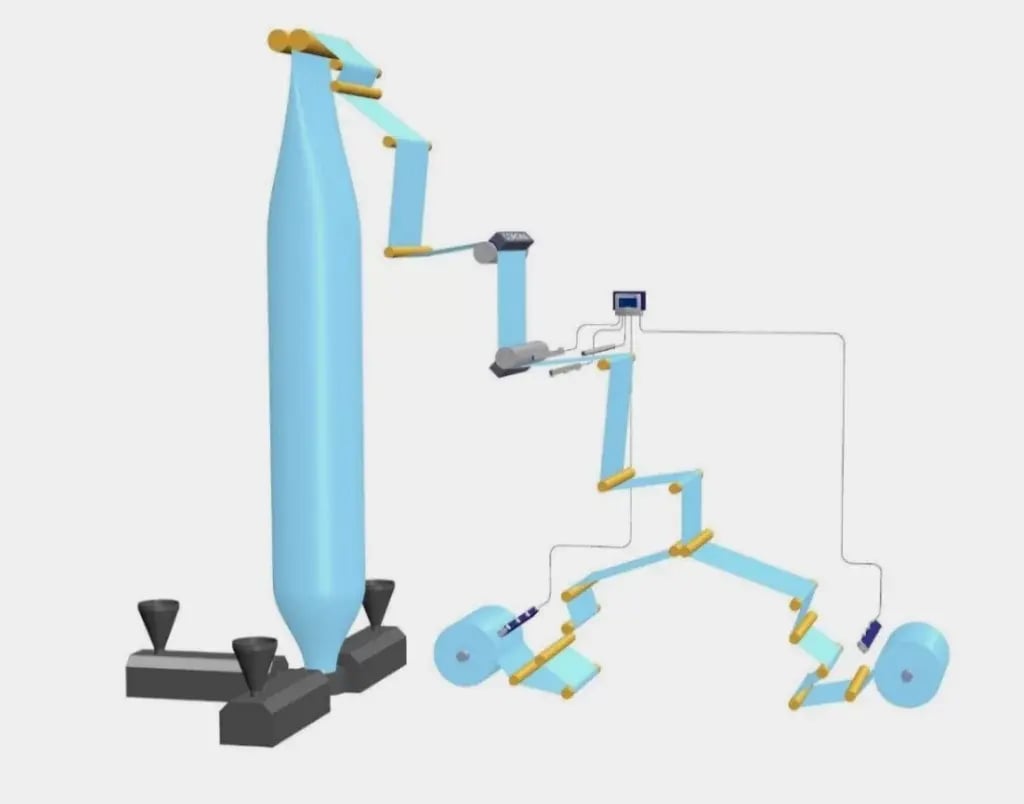

Blown Film

Prevent Static Shocks on Blown Film Lines

Blown film extrusion is widely used to manufacture packaging films, many of which are multi-layered. This layering enhances mechanical strength, transport properties, and thermal resistance, as required by sectors such as food and healthcare. The height of the blown film “bubble” is essential for cooling the material before it reaches the nip or top rollers. Static charges can be identified by shocks or visible sparks caused by discharge.

Once the material passes through the nip (top) rollers on the blown film line, it begins to generate static electricity, accumulating high levels of charge. This occurs due to friction across multiple rollers and temperature changes as the material cools. If the film goes through a corona treater, the static charge becomes even greater. At this stage, an additional section of static eliminators, ideally equipped with inline static measurement (Closed Loop Feedback), is strongly recommended.

On the final winder(s), long-range static elimination bars are installed to neutralise the material during winding. Using the ThunderION IQ static eliminator ensures complete neutralisation of the film, from small-diameter rolls to large-diameter ones.

This process prevents dust attraction, telescoping of the finished roll, and unpleasant shocks to operators. For double-layer (tube) material, static elimination is crucial to allow the film to be opened after unwinding. In some cases, discharging before winding is necessary to achieve a low static level on the finished roll. Typically, 24V static eliminators are used for this purpose.

Contamination of static eliminators is a critical concern. To maintain efficiency, this can be continuously monitored by the Manager IQ Easy or Smart SLC.

If efficiency falls below a set threshold, the operator or PLC receives an alert. Maintenance will then be required on the contaminated static bars.

For advanced functionality, the IQ Easy System can be directly integrated with the blown film line via a Fieldbus connection. This enables collection of all key data regarding static equipment performance and maintenance needs, as well as logging the static charge levels on the material.

The result is high-quality, cost-effective blown film production

Bond Two Materials

The Problem

Static charge between two surfaces can create enormous adhesion forces. These forces can also be used in a productive way in all kinds of production applications e.g.

- Keep materials together to prevent shifting during cutting, punching, laminating or packaging

- Position a label for In mould labeling or on a magazine prior to packaging

- Keep extruded film on the cooling roller to prevent shrinking

The Solution

The materials need to be bonded have to pass a charging electrode. Opposite to the charging electrode a ground reference is positioned, e.g. an idle roller. A static charge can be applied ranging from 3 kV to 120 kV depending on the material thickness, speed and adhesion force required. Used equipment in this application:

- HDR and CM5

Slitting and Rewinding

Slitting and Rewinding: Managing static during high-speed operations

Slitting and rewinding is the process of cutting jumbo rolls of various materials into narrower widths at very high speeds. This method is suitable for a wide range of substrates, including paper, plastic film, flexible packaging, and textiles. During the process, the web is unwound, guided through the slitter/rewinder, and passes adjustable knives before being rewound onto one or more shafts to create smaller rolls.

Handling foil slitting and rewinding is standard practice today. However, due to the high speeds and multiple rollers involved, static electricity can become a serious issue.

To counter this, 24V Performax (IQ) Easy Speed ionisation bars are installed immediately after slitting and before winding. These static elimination bars neutralise the charges generated during unwinding and slitting, preventing:

- New static build-up during winding

- Attraction of cutting dust

- Static shocks to operators

- Telescoping of finished rolls

If a specific low static level is required on the final product, an inline measurement system provides the solution. The IQ Easy System offers real-time monitoring and control through a fully managed Closed Loop Feedback (CLFB) system.

This system supervises all connected static eliminators and integrates directly with the machine PLC via Fieldbus. It delivers complete data on efficiency, maintenance needs, and static charge levels, including alarms. Inline measurement and data logging of electrostatic levels can also support quality reporting.

These features enhance static control, operator safety, and product quality—resulting in efficient, high-quality slitting and rewinding.

Folding Machines

During feeding, an electrostatic charge is created that causes the top sheets to stick together. This usually results in a paper jam and consequently a machine stoppage. Blowing with ionising air nozzles separates the top sheets and neutralises the static charge, allowing them to be removed from the stack individually. An ionisation bar just before the paper stack ensures that the individual sheets move. Friction generated by folding creates electrostatic charge again, causing registration problems at the fold opening, resulting in incorrect folds. An ionisation bar eliminates the static charge and prevents folding problems. Upon delivery, an ionising bar ensures a neat stack.

Used devices:

Placing Labels

With perfectly bound lines, card inserts often overshoot the target area due to the line speed. It is also possible that the speed does not exactly match the line speed, causing the card to slide backwards, resulting in poor positioning on the packaging. Apply a static charge with the charging bar to the card when it hits the page to effectively hold the card in place.

Used devices:

Electrostatic Blocking

Magazines, pamphlets or books coming off a machine are transported via an automatic line to the wrapping or palletising machine. Before they arrive there, they are stacked in a sorting machine. Once the bundle leaves the turntable of the stacker, the sudden speed of movement of the machine can cause the unstable packs to shift or fall over. Compensating stackers are equipped with electrostatic charging bars at the top and on both sides, with opposite polarities, which stabilise the bundles of magazines into ‘brick-like’ stacks to ensure safe further transport.

Used devices:

Flow Wrapper

Packaging film is unwound and formed into a tube, while the product flows over a belt into the tube with film. The film is overlapped at the top or bottom. The overlap is necessary to ensure that the two ends of the film are tightly pressed together. To prevent the film from tearing in the shrink tunnel, a heat seal or electrostatic charge is applied.

The electrostatic electrode uses less energy than the heat sealing system. It also requires no maintenance, and the end product is easier for the end user to unpack.

Used devices:

RFID Tags

RFID tags contain an antenna that allows them to receive and respond to radio frequency queries from an RFID transceiver. The microchip in an RFID tag can be damaged by static electricity. Static charges are common during the printing/production of tags and labels, anywhere along the path from the supply roll to the rewinder. The charges are generated by the contact and separation of the web material as it moves over the various rollers and process stations while passing through the press or processing equipment. Unfortunately, the small circuits of RFID tags may not be robust enough to withstand exposure to static charges.

Used devices:

Form Fill Seal Machines

Vertical forming, filling and sealing processes often result in the finished packaging being rejected because product dust adheres to the film in the sealing area. By placing an ionisation nozzle just below the filling tube, you neutralise the static charge, resulting in a clean seal. To prevent the film from sticking to the shoulder/former, place an ionisation bar over the flat film just before forming to neutralise the static charge.

Used devices:

Label punching, perforating labels

Label punching machines can punch labels from printed roll material at high speed. After unwinding, the film is aligned and the labels are punched with high precision. Stacked labels with a high static charge can cause problems during destacking. Compact VicinION ionisation bars are mounted just before the punching section to neutralise the film on both sides so that the labels are stacked without static charge.

Blow Moulding

A thin piece of molten plastic, called a parison, leaves the extruder's mould head and falls vertically between the sides of the open mould. The parison has a high static charge and tends to bend and pull towards the grounded metal mould. This leads to quality defects in the blown bottles. When using multiple mould heads, the parisons have a static charge with the same polarity, causing them to repel each other, which often results in rejected parts. Heat-resistant ionisation rods eliminate static charges and prevent production disruptions and machine stoppages due to the negative effects of static electricity.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Maik Zimmer, Technical Sales

“Static can disrupt packaging processes, from misfeeds to label errors. Simco-ION visits your facility to provide customized solutions that keep operations efficient.”