Wood Industry

Discover how you can apply Simco-ION products in your wood manufacturing business

Applications for the Wood Industry

Simco-ION offers solutions to control static electricity in the wood industry like for chip wood press machines. Neutralising and cleaning woodpanels before paintspraying. Using a static charge to temporally bond Melamine (decorative) paper to chipwood panels during transport to the press. Using ionising air nozzles will prevent sawdust attraction on CNC machining in the wood industry. Eliminating static on Edgebanding machines will reduce dustattraction.

Used devices:

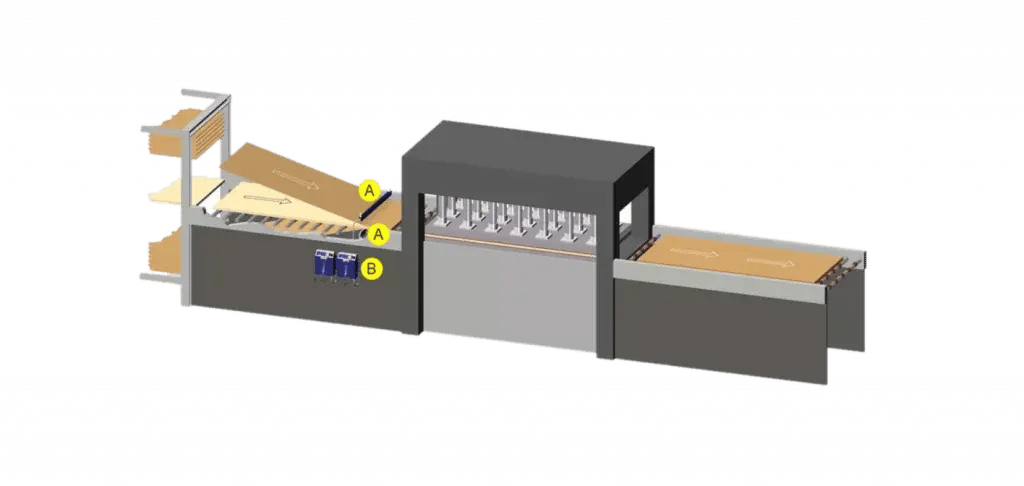

Chipwood Presses

In the chipwood industry decorated paper, impregnated with synthetic resin and hardener, is usually put on both sides of the chipwood panel. The sandwich is then transported into the press. During this process the problem occurs that the decorationpaper slides due to the sudden movement, so that only a part of the chipwood remains covered. The panel becomes waste. Simco-Ion advises to use charging bars, to be installed above and below the chipboard just before the sandwich is moved into the press. Applying opposite polarity electrostatic charge to both sides of the panel will prevent the paper to move.

Used devices:

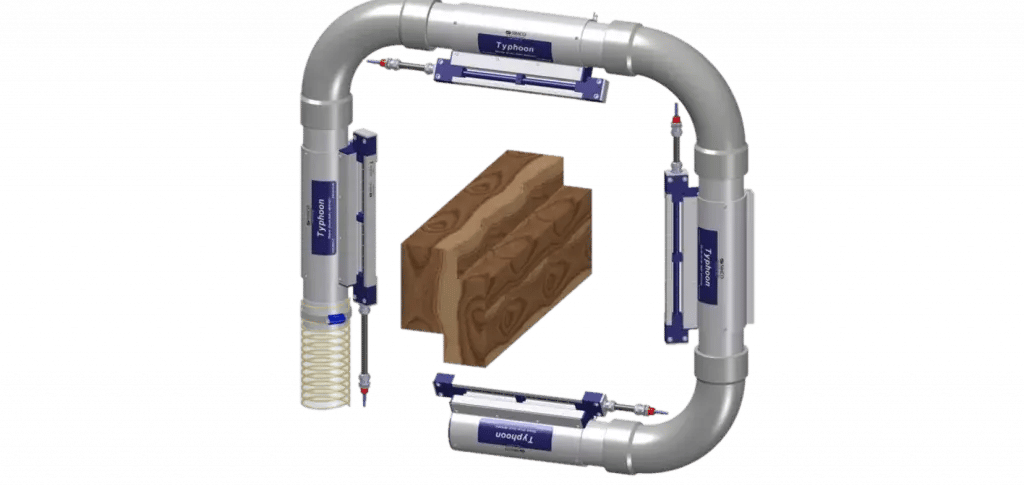

Cleaning Wood

TYPHOON Static Control Air Knife Systems are custom-designed to provide superior heavy-duty surface cleaning. They perform like compressed air knives, but use a blower instead of compressed air, reducing operating costs by 30% to 70%. Combined with Simco-Ion's static elimination bars, TYPHOON becomes a powerful tool for removing dust and dirt from profiles and wood.

Used devices:

CNC Milling

Computer Numerical Control (CNC) milling, is a machiningprocess which employs computerized controls and rotatingmulti-point cutting tools to progressively remove material by drilling/milling the workpiece and produce a customdesigned part or product.Machining (laminated) panels, plastics and composites creates static charges due to friction. Mounting a Blowflex Easy with flexible nozzle on the moving CNC head can eliminate static charges on the product and swarfs/chips and improves finishing results

Used devices:

Edge Banding

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. An edge bander bonds the edge banding to the substrate and trims the edges. Friction and temperature fluctuations will create a static charge on the edge banding material, swarfs (and dust) created by the trimming section can be attracted by this static charge. Blowing ionised air with a Blowflex Easy will neutralise the edge banding material and prevents dust attraction, this results in a good quality end product.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Rob Achterkamp, Sales Consultant

“Static attracts dust and slows down sanding and coating processes. The right solution ensures consistent quality and reliable production.”