Style Guide

The perfect template to dial in your theme settings.

Specialised Applications

(IML and Perforation Detection)

Specialised Applications

Discover the benefits of Simco-ION products

On this page, you’ll learn about the role of IML and perforation detection in industrial processes, the situations where accuracy and reliability are essential, and the Simco-ION solutions designed to meet those needs. From advanced systems for in-mould labelling to specialised tools for detecting perforations, we provide the technology to keep your operations efficient, your products consistent, and your workplace safe.

Click on the buttons above to jump straight to the associated paragraph

IML In-Mould Labeling Process

In Mould Labeling (IML), or static placement (static bonding), is the standard in the injection moulding, thermoforming, and blow moulding IML industries. Instead of conventional methods like decorating products by printing directly or placing an adhesive label onto the product, the decoration is achieved with a pre-printed plastic polypropylene (PP) label. The pre-printed PP label is inserted in the mould and then the molten PP is added. The label fuses with the product, which takes the shape of the mould.

Benefits of Using (Static) IML Label Application

-

Eliminates screen printing, label application, or pad printing on the product

-

No corona or flame treaters needed to prepare the surface

-

Higher quality graphics

-

Rapid changing of graphics possible

-

Recyclable with label material same as moulded product

-

Hygienic results for the content

-

Less storage space, press to final packaging

-

Single-step production method for cups and buckets

-

Less handling, less costs, less storage

How the IML Process Works

In the injection moulding process, a pre-printed IML label is picked up by a robot and placed in the mould cavity, where it sticks due to electrostatic charging. After closing the mould, the label is moulded together with the end product, producing a finished, fully recyclable item. Electrostatic IML also makes mould construction simpler and cheaper compared to vacuum techniques, and avoids production interruptions caused by cleaning vacuum channels, resulting in high-output, competitive production.

Static Charging Technology for Label Placement

There are three different charging methods for IML:

-

Electrostatic Pinning: Charging the label inside the mould using high-voltage generators

-

High-Speed Direct IML Charging: Charging the label inside the mould with semi-conductive material (patented by Simco)

-

Simplified IML for Metallic Labels: Charging the label outside the mould and transferring the charged label into the mould

Depending on the product geometry and cycle time, various IML electrodes are used:

-

Emitter pins in the core (IML spider)

-

Constructed core with IML foam

-

Constructed core with IML Easycore

-

Simplified versions with external charging electrodes

High-voltage cables are specially designed to be rugged and flexible for robot applications.

Static Label Placement in Mould – IML Electrostatic Label Placement (Pinning)

Outside the mould, inside the injection moulding machine, the robot picks up a single pre-printed PP label onto a dummy core and transports it (high-speed) into the mould cavity (single or multiple). When the label reaches its final position in the mould, it is electrostatically charged using the Simco-Ion CM-Lite high-voltage generator or static generator and the connected charging electrodes (spider pins) in the dummy core. After charging, the label transfers to the grounded mould wall where it sticks due to the electrostatic charge. The robot arm then retracts, and the moulding process proceeds as usual.

For this IML process, Simco-Ion developed a special rugged and flexible high-voltage cable suitable for cable chains in robot applications.

Simplified IML for Metallic Labels

In this method, the dummy core is created with semi-conductive resin (EasyCore) and connected to machine earth. The label is charged outside the mould with a standard charging bar and CM5 charging generator, then transported by the robot into the mould. Electrostatic forces cause the label to jump to the mould wall, allowing even metallised labels to be placed accurately.

High-Speed Direct IML Charging

Simco-Ion’s patented Direct IML Charging allows label placement without non-isolated high voltage inside the mould, using lower voltage for better adhesion. A pre-printed label is picked up onto a dummy core made of semi-conductive material (IML-Foam or EasyCore) and transported into the mould. The label is charged by the CMME high-voltage generator mounted on the robot arm, transfers to the grounded mould wall, and fuses with the molten PP to become the finished product.

The Charge Master Micro Easy (CMME) reduces cycle time through Cycle OK Feedback and can be mounted on the robot arm for even faster production.

IML and Industry 4.0

The CMME can be extended with the IQ-COM module, enabling direct connection to the machine PLC via Ethernet-IP, EtherCat, or Profinet. This allows full monitoring and control of the IML process within Industry 4.0 frameworks.

Expertise and Support

Whether you are an end-user or a robotics manufacturer, Simco-Ion provides advice and knowledge to create the perfect IML solution. Our dealer network offers local expertise to help select the right labels, electrodes, and generators to ensure a successful IML project.

To find technical support or discuss your IML project call: +31 (0) 573 288333

Or find your local representative HERE.

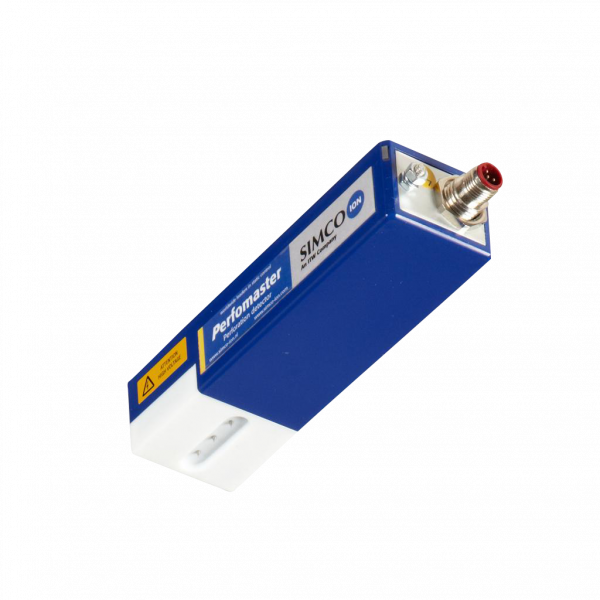

CMME

The CMM (IQ) Easy is a small profile footprint charging generator specially designed for IML applications. The unit has fully integrated high voltage parts and only needs a 24V DC supply. The housing is compact, robust and only weighs 480 grams which makes it perfect for end of arm mounting in IML pick and placehandling systems. It can easily withstand the high G-forces occurring during the IML process.

IML Easycore 2 Component

Simco-ION's patented IML charging technique for use in IML robot applications is even more versatile with the IML Easycore 2 component.

IML Spider

The IML Spider is a versatile electrode for direct charging for IML applications. It consists of a IML Spiderblock with built-in resistors to prevent accidental sparking. The IML Spider Block has 8 output ports, with resistors per port, for connection of up to 8 flexible charging electrodes. An additional output port is provided for daisy chaining complementary IML Spider Blocks. All connection ports are equipped with quick connect plugs.

In many production processes, it is necessary to detect perforations and leaks in injection-moulded products, films or other products like gloves and delicate material for applications in the medical industry and for medical use. Existing methods such as vacuum, pressure or optical control are often not applicable to transparent products or shapes that are difficult to handle. High voltage sparks can be used in a controlled way to detect perforations in these cases. A spark from a special electrode to a ground reference can be detected by the high-voltage generator and counted or relayed to other connected electronics and evaluated. The detection is non-contact so that there is no contamination of the material during hole-detection. High voltage electrostatic perforation detectors like the small footprint, Perfomaster and the CM 5 high-voltage generator provide the hardware and the software to generate a controlled spark, detect this spark and convert the spark to a pulsed signal for use in other equipment.

Processing the spark!

The pulse signal is available on the output connector and can be used for hole detection or counting the detected spark-overs for perforations detection.Perforations in plastic webs and products can be detected and counted. Perforations in moving webs can be detected with a special detection bar and a high voltage generator. Perforations will be detected but not localised. A perforation in the film will create a spark through the material and will generate an output signal on the charging generator. Due to the strong electrical field placement of anti-static bars after the perforation detection is mandatory. Perforations in products can be detected using high voltage to create a spark through the perforation. Common application is testing the injection point of injection moulded products e.g. yoghurt cups, bottles and containers.

Perforations in a web material can be used to determine the position of the material in the machine. The perforation can be the “tear-off perforations” of bags or a deliberate perforation made to determine a position. Perforation detection with the use of high voltage is not depending on the material surface and can also be used with transparent materials. When a perforation passes between the high voltage electrode and a ground electrode, a spark is generated. This spark will be detected and a pulse signal will be available for use by the machine control system.

Perfomaster

The Perfomaster provides the hardware and software to generate a controlled spark over, detect this and evaluate the spark over to produce a pulse signal. The pulse signal is available on the output connector and can be used for counting the detected spark-overs and thus perforations.

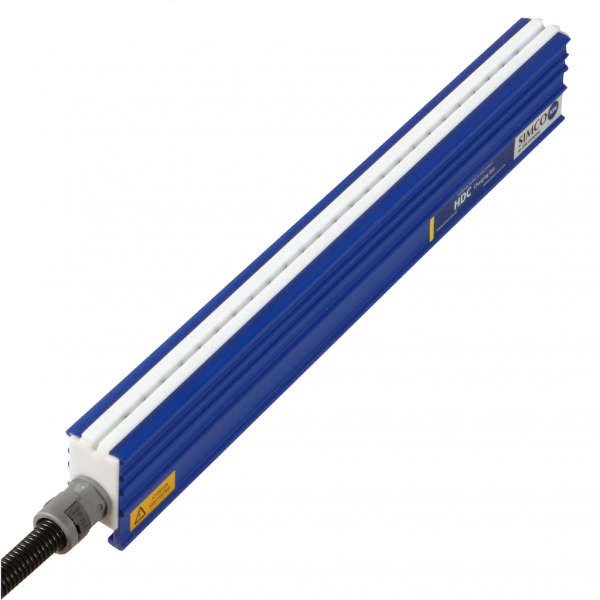

HD DET

In order to detect perforations in a moving material web, this special electrode is equipped with a resistance per emitter. When a perforation passes the electrode, there will occur a controlled spark over.

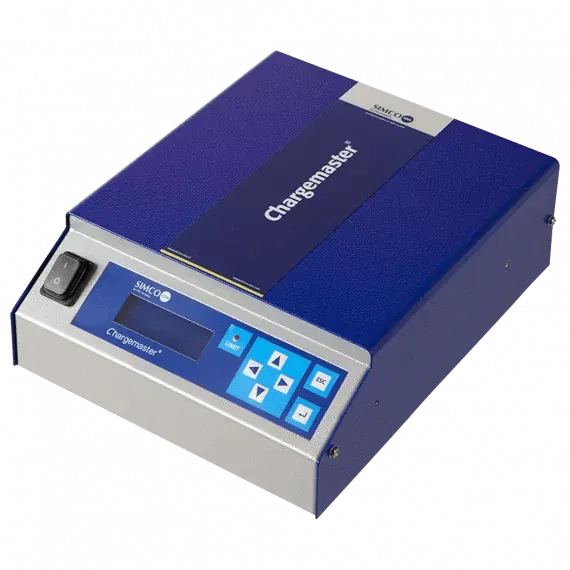

CM5-30

CM5 is fully backwards compatible with ECM30/60 and ECM DI30/60.

For basic users a quick set-up menu is provided to set-up the generator to function as an ECM30/60. The Menu is available in English, German, French and Italian.

Rob Achterkamp, Sales Consultant

“Static electricity improves precision in IML and brings unmatched accuracy to perforation detection. Feel free to reach out to see how we at Simco-ION can help.”

Typography

You have the ability to have different typography settings for your website and landing pages which is what you see below. You can also control your blog posts typography seperately in the theme settings.

Heading 1

Heading 2

Heading 3

Heading 4

Heading 5

Heading 6

Morbi ultricies, this is a text link nibh quis tincidunt scelerisque, magna purus malesuada erat, feugiat semper urna lectus at sapien. Maecenas ornare, metus ut mattis vehicula, nulla nulla efficitur lacus, vitae congue nisi nibh eget massa. Sed nec pharetra mauris, ac volutpat metus. Praesent sed enim mollis, tincidunt orci sit amet, mattis risus.

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

In sit amet massa sed dolor tempor mattis id et tellus.

Icons

You can set a global default color for icons and will also have control in each module to select a specifc color if needed.

CTAs & Standard Buttons

You can set up various button styles to create a visual hierarchy. Pro-top: Make the Primary button pop the most.

Modal Popup

Modals pop-ups are features of various modules. You can give them global style.

Modal Headline

Donec sed pretium mauris. Suspendisse aliquam ornare quam, eleifend sagittis mauris interdum eget. Maecenas placerat mattis velit, in egestas erat vulputate vel. Morbi at nisl justo. Praesent quis erat risus.

Praesent varius quam quis ultricies consequat. Aenean ullamcorper commodo consectetur. Vivamus ex sapien, ullamcorper id ullamcorper in, eleifend in quam. Curabitur ac metus convallis, scelerisque libero in, vulputate justo. Mauris erat ex, commodo vitae ipsum et, vestibulum porttitor odio.

Forms

Create a form that has input fields, dropdowns, checkboxes, and everything. Then style it here.