Printing & Coating Industry

Discover how you can apply Simco-ION products in your printing & coating manufacturing business

Applications for the Printing & Coating Industry

Simco-ION offers solutions to control static electricity in printing processes like offset printers, Silkscreen printers or Flexoprinters. Thus ensuring longer production runs in Digital (UV) Flatbed printers due to static elimination on the printing heads. Removing static charges between sheets at the infeed of Offset printing processes will prevent production stops and misalignments. ATEX certified static eliminators eliminate sparks in solvent processes avoiding fires. Low static levels in Digital printing processes will assure long and high quality production runs also in Roto Gravure processes.

Digital Inkjet Printing

Static electricity creating problems in digital inkjet printing

Digital printing is becoming popular in more and more markets nowadays. However static electricity can create a lot of problems like (printing) errors. Problems that can occur are dust attraction, bad (un-sharp, blurry) printing results or dirty printing heads (so short production runs). Even machine stops can be caused; all resulting in more expenses, so non-competitive printing.

Manufacturers who (single pass) digital-print flat surfaces like paper, cardboard, wooden floorings and especially plastic sheets can experience multiple problems in their printing sections caused by high static charges. To solve this issue, different static measurements are made to learn exactly where the static is generated and where to neutralize, using a FMX field meter or inline static measurement.

During de-stacking, the single sheet wants to stick to the pile because of static: blowing ionised air between the sheets with our Blowflex with flat nozzle or air-knifes with antistatic bar will solve this problem so only a single static neutral sheet will enter the line. During transportation, the sheet is cleaned by ionised air, using the Typhoon system or using a (rotating) brush in combination with an industrial static eliminator. After corona treatment of the plastic sheets again discharging is needed to make sure the treated sheet continues its way without static charge.

When entering the digital printing area with several printing heads, a predefined low static level is needed to guarantee high quality printing and continuous clean printing heads which results in long production runs. To achieve this, our Simco IQ Manager System can offer real-time managing and monitoring options with a full controlled Closed Loop Feedback system (CLFB). This system monitors and controls all connected static devices and can be directly connected to the machine PLC via Fieldbus connection. In-line measuring and datalogging of static charge levels can be used in quality reporting.

This provides all information about the efficiency and required maintenance of the bars, as well as the static charge including alarms and other options to increase the control of the line, safety and quality which all results in high quality competitive digital printing!

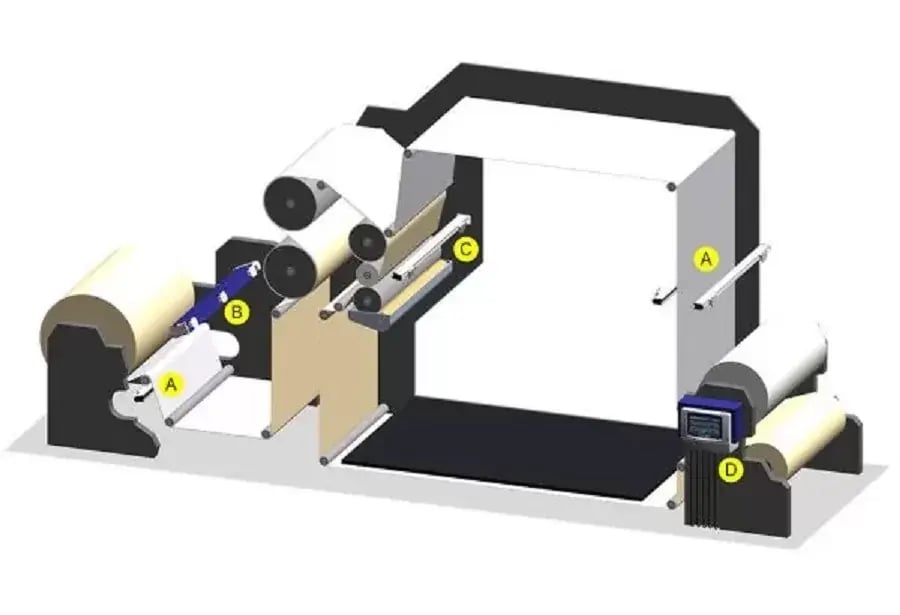

Coating Machines

Static electricity creating fire in coater section?

Manufacturers of packaging can experience multiple fires in their coating section caused by sparks from high static charges. Operators facing this issue turn to industrial antistatic solutions to help solving these static problems.

Each machine section can require different anti-static bars as the distance to the material varies. Also different type of rollers which the material passes influence the level of static charge on the web. Special attention for safety is required when it concerns the Ex-area, where only ATEX-approved electrostatic eliminators are allowed.

Different measurements must be made to learn exactly where the static is generated and discharging is necessary. To measure the exact static charge a handheld FMX field (static) meter is needed or an IQ Sensor bar for in-line measurement.

Unwinding plastic film can create static charges up to 20kV or more and the web needs to be neutralized directly after unwinding. Installing a high performance discharging bar also prevents that static charge will attract dust particles. If the material passes a corona treater, a massive static charge is created on the material and a discharging section (in Close Loop Feedback; CLFB) is recommended. Before the material goes into the coating section (ATEX-zone), both sides of the material require discharging to prevent the existing static charge acting as a possible ignition source that could result in a fire.

Inside the coating section the material passes multiple rollers and static is re-created. ATEX certified ionisation bars are neutralising the static charge on both sides of the web to prevent static charge acting as a possible ignition source. The pollution and efficiency level can be monitored by the IQ manager. If the efficiency goes below a preprogramed level the PLC or the operator receives a warning so he can service the indicated ionisation bars. During the drying process the material can re-charge again because of the temperature fluctuations in the dryer. Here and also before the laminating process 24V ionisation bars will neutralize the web and prevent static from encapsulating between the layers.

At the final (re)winder the material can once again create high static charges due to the pressure rollers, causing operators to get shocks when near to the material. As the distance to the material changes at the winder, a ThunderIon IQ is required to effectively eliminate the static charges created during the final winding. Additional demands regarding static charge or ensuring personnel safety can be created using an IQ Easy System with in-line static measurement and Closed Loop Feedback-technology. The Smart SLC or our IQ Manager can be directly connected to the coating lines PLC via Fieldbus connection. An alarm level alerts the operator in case the static charge reaches a dangerous level. In-line measuring and datalogging of static charge levels can be used in quality reporting. This is how the Manager IQ System provides all essential information to increase personnel safety and reduces the chance on new fires to a minimum.

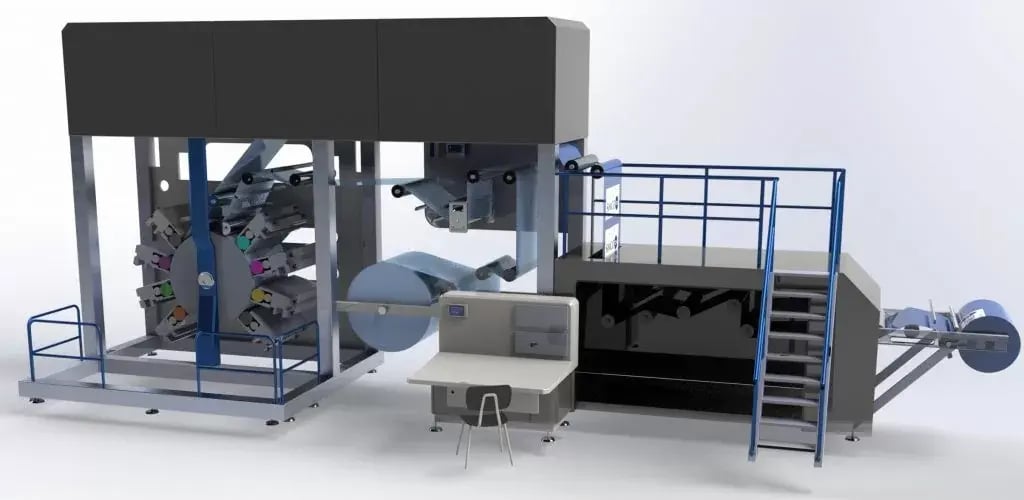

Flexoprint Machine

Full static control on flexoprinting machines

Flexographic printing lines as well as other printing presses are developed to produce flexible packaging in a variety of colours and finishes at high speeds. You can recognise static electricity by experiencing static shocks or seeing sparks as a discharging effect also printing issues like the following can have static as a cause:

- Ink mist

- Ghosting

- Fuzzy printing due to static

- Particles on the print

- Dust attraction due to static

- Print defects due to static

- Overspray due to static

All effects can be static electricity(high-voltage static) related issues. Static charges can create problems in many sections of the flexoprinter or flexopress.

Discharging the web

Discharging the web directly after the unwinder will prevent that a static charge will attract dust particles. Also operators will not get any shocks while passing or touching the web during production runs.

Corona treater

When the film passes a corona treater a massive static charge is created by the corona unit on the material. After the Corona treater a discharging is recommended (in closed loop feedback).

Flexoprinting Section: Static Safety in EX Zones

When the flexoprinting section is classified as an EX area (due to solvent use), static charges on the material can ignite vapours and cause fires. To prevent this risk, it is essential to neutralise and monitor static just before the material contacts the central printing drum. This can be achieved using our ATEX-certified devices, such as the Sensor IQ Easy EX and Performax IQ Easy EX. These systems actively measure and control static levels, ensuring safe operation and enabling long, high-quality production runs.

After printing, the material may accumulate static again in the dryer. Installing ionisation bars allows continuous neutralisation before the film moves to the next section of the machine.

Winding Station

On the winding station, anti-static bars and a sensor bar (in closed loop feedback) are installed to neutralise the material during winding, this will also prevent possible static shocks to the operator that performs the roll change. Another effect that can be prevented by discharging the material is the telescoping end roll effect.

In-line measuring and datalogging of static charge levels during winding can be used in quality reporting. The IQ Easy System can be directly connected to the PLC of the flexoprinting machine via Fieldbus connection. An alarm level alerts the operator in case the static charge reaches a dangerous level. This is how the IQ Easy System provides all essential information to maintain high speed, high quality and competitive flexoprinting.

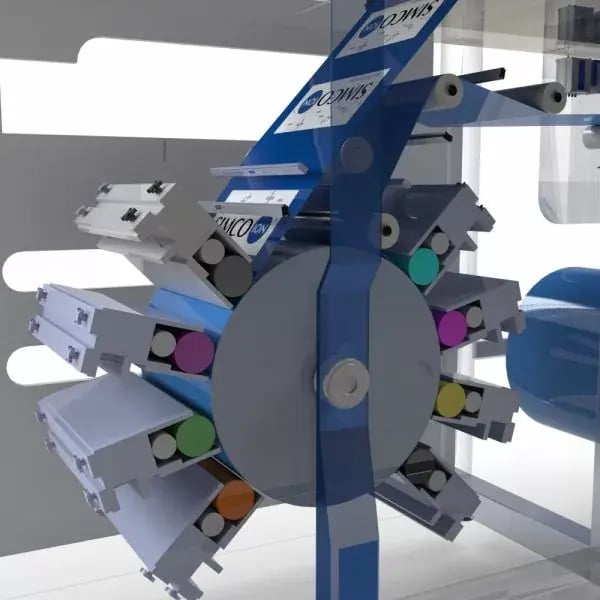

Rotogravure

Problems and solutions for static electricity in rotogravure printing

Rotogravure printing is specially developed for large, to very large graphic runs by using a rotogravure press. During the gravure printing process the printing cylinder rotates in the ink pan where the engraved cells fill with ink. As the cylinder rotates clear of the ink pan, any excess ink is removed by the doctor blade. Further around, the cylinder is brought into contact with the substrate, which is pressed against it by the rubber covered impression roller.

An electrostatic charge is created on the surface of the material, as it travels through the printing machine with continued contact and separation events, complicated by the speed of the process. The surface charge can build to potentially hazardous levels at the rotogravure print section, where the use of solvent based inks creates a dangerous situation. A spark from an electrostatic discharge can ignite the solvent/oxygen mixture, which ultimately can cause a fire. ATEX approved static eliminators will neutralise these static charges before and after the print station, allowing for static free and safe rotogravure printing. Simco-Ion also recommends static control equipment at the unwinder and winder sections, to avoid shocks to operators and the attraction of dust particles, caused by static electricity.

Inside each printing section the material passes multiple rollers and a static charge is created. ATEX approved static eliminators, such as the Performax Easy (IQ) EX, are neutralising the electrostatic charge before and after printing to prevent static charge acting as a possible ignition source. Pollution on the static eliminator, by ink or dust, is recognised so the static efficiency level per printing station can be monitored by the Manager IQ. If the efficiency goes below a preprogramed level, the operator receives a warning so he can service the indicated static eliminators.

At the winding section the material can once again create high static charges due to the pressure rollers and causing operators to get shocks when near to the material and creating the telescoping effect on the end rolls. As the distance to the material changes at the winder, a ThunderION IQ or Performax IQ Easy static eliminator is required to effectively eliminate the static charges created during the final winding. Additional demands like a predefined static level or ensuring personnel safety, by using a IQ Manager System with inline static measurement and Closed Loop Feedback-technology, is possible. The Manager IQ or Smart SLC can be directly connected to the printing line PLC via Fieldbus connection. An alarm alerts the operator in case the electrostatic charge reaches a dangerous level.

The IQ Easy System provides all essential information to increase personnel safety and reduces the chance on fires to a minimum, so high quality and competitive rotogravure printing is guaranteed.

Used devices:

Digital UV Flatbed Printing

How to deal with static electricity on digital (UV) flatbed printers?

Digital flatbed UV printers are capable of high quality printing on a wide variety of materials such as photographic paper, film, cloth, plastic, pvc, acrylic, glass, ceramic, metal, wood or leather. These printers can use special UV (Ultra Violet) curable inks that are exposed to UV-light to cure.

The new Cleanflex Easy 24V anti static blowgun can be used to neutralise electrostatic charges on the material before printing; f.e. high electrostatic charges (measurable with a Simco-Ion static meter FMX-004) will occur by removing protective film from plastic sheets.

By neutralising you will prevent the attraction of dust particles and simplifies placement on the vacuum table. An industrial anti static blowgun can be used to clean the material before printing, the pull down function from the anti-static blowgun makes it easy to use.

Simco-Ion advises to neutralise the material in free air and not while it is laying on the bench (vacuum table) of the flatbed printer. When a charged sheet is in free air the electric field moves in all directions and is available to be measured and neutralised. When the sheet is however flat on a (conductive) bench the electric field is attracted to the bench and is not available to be measured or neutralised.

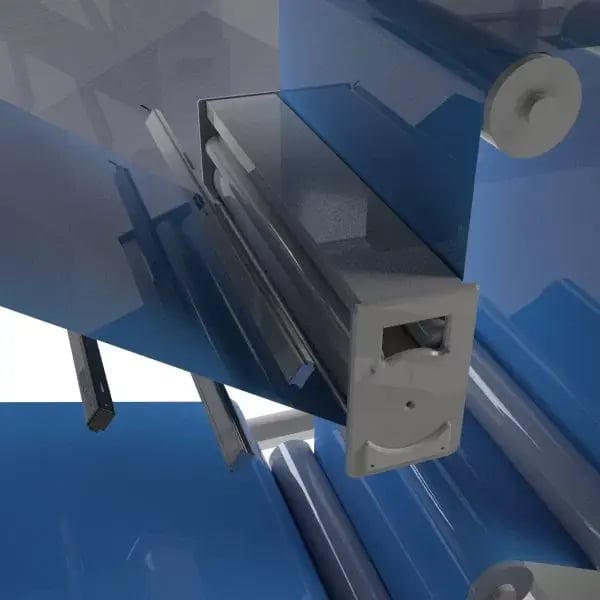

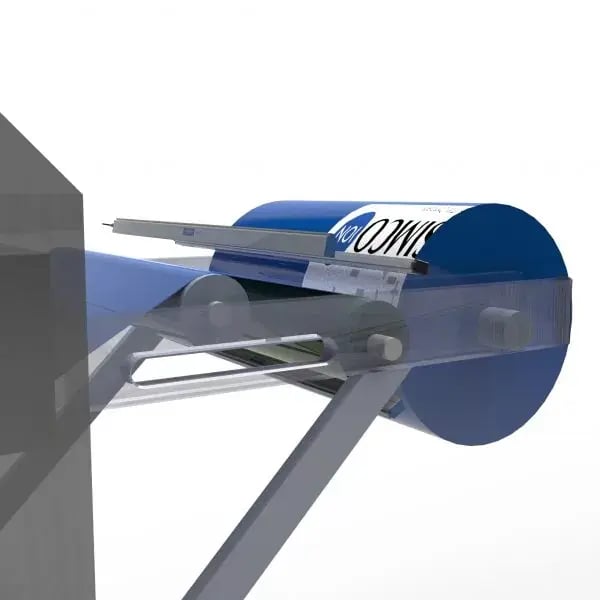

Positioning compact Simco-Ion 24V electrostatic eliminators on both sides of the printing head will make sure that during printing static charges are eliminated. This will prevent unsharp/blurry printing results. Also contamination of the printing heads is reduced, resulting in longer production runs.

Most digital UV flatbed printers have a roll to roll option, to print on flexible media rolls. By positioning static eliminators on the printing head also electrostatic charges will be eliminated while printing these rolls. With specific material it might be needed to neutralise directly during unwinding/winding the flexible material from the roll.

Tampon printing

There are two main problems caused by electrostatic charges. The pad, a silicone-based product, touches the product to be printed. The deformation of the pad creates a static charge and fine paint splashes can end up on uwanted parts of the product or on the pad. An ionisation bar neutralises the pad on its way to and from the printing block and solves this problem. In addition, contamination on the surface of the product, attracted by static electricity, can be picked up by the pad and remain stuck, resulting in misprints for all subsequent products. An air-assisted ionisation bar cleans the product before printing, ensuring better prints and fewer rejects.

Used devices:

Digital Printing

Digital printing technology has made significant progress, and Printing On Demand (POD) is now widely recognised and used. Digital technology offers printers with great flexibility for personalised, secure and financial documents. When entering the digital printing environment with multiple print heads, a low static level is required to ensure high quality, high speed and continuously clean print heads. A compact VicinION ionisation bar can be placed in front of the print heads to ensure long production runs of high quality.

Silkscreen

The stack at the feed end of the printing machine may have a static charge, causing the material (the substrate) to stick to the stack and enter the machine incorrectly. Once the squeegee has completed its printing movement and the screen is lifted, the substrate may stick to the screen, causing smudges. The substrate may also stick electrostatically to the screen bed, causing misalignment. Misalignment on its way through the dryer, incorrect stacking on delivery, attraction of airborne contaminants, these are all problems that Simco-ION products can solve, preventing issues and machine stoppages.

Used devices:

Offset printing

Static electricity can cause malfunctions in high-speed printing presses. During feeding, sheets can stick together, resulting in misregistration and machine downtime. Our Blowflex blows ionised air towards the paper to separate the top sheet from the stack. The top sheet is then fed into the machine and can be neutralised in the open air as it passes under the bar mounted on top of the stack. Neutralisation on one or both sides at the delivery section ensures a neat stack.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Pietro Sabatino, Technical Sales

“From paper jams to dust attraction, static creates real problems in printing. We work directly on your lines to solve these challenges efficiently.”