Converting Industry

Discover how you can apply Simco-ION products in your converting manufacturing business

Applications for the Converting Industry

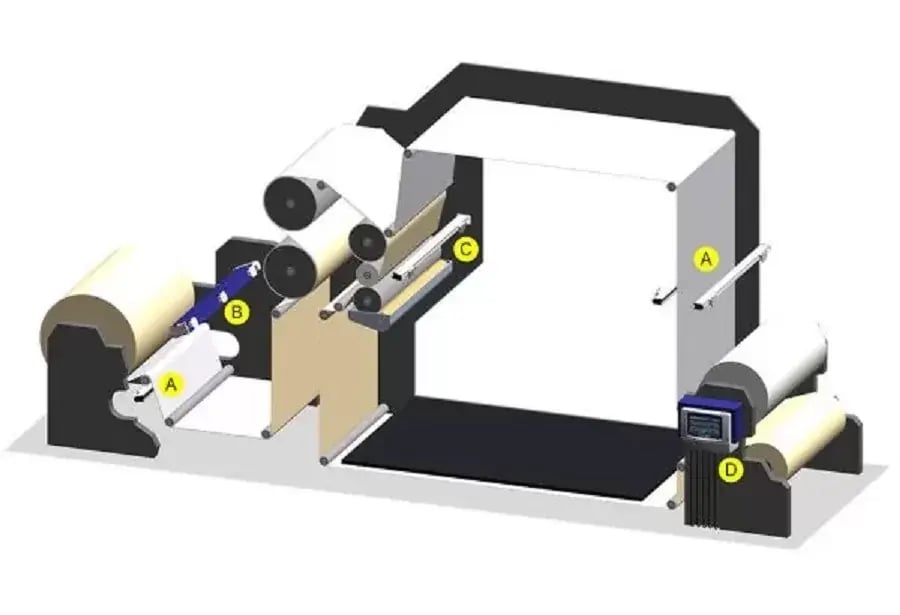

Simco-ION offers solutions to control static electricity in converting processes like Slitting / rewinding. Stacking after sheeting processes and static free winding on Slitter machines and winders. Using a static charge can prevent air inclusion during bag making or Sheeter. Our IQ manager gives total static control in Coating/Laminating processes; including elimination and in-line measuring of static charges, setting alarm levels and data logging.

Coating Machine and Fire Hazards

Preventing Fires from Static in Coating Lines

Packaging manufacturers often face fire risks in coating sections caused by sparks from high static charges. To address this, operators rely on industrial anti-static solutions to eliminate these hazards.

Each part of the machine may require different types of anti-static bars, as the distance to the material varies. The roller types also influence the level of static on the web. Extra safety measures are essential in EX zones, where only ATEX-certified static eliminators are permitted.

Accurate measurement is key to identifying where static is generated and where discharging is needed. This can be done using a handheld FMX static field meter or an IQ Sensor bar for inline monitoring.

Unwinding plastic film can produce charges of 20kV or more, so neutralisation immediately after unwinding is critical. Installing high-performance discharge bars also prevents dust attraction. If the material passes through a corona treater, static levels rise significantly, making a discharge section with Closed Loop Feedback (CLFB) highly recommended. Before entering the coating section (EX zone), both sides of the web should be discharged to eliminate any ignition risk.

Inside the coating section, static is regenerated as the material passes multiple rollers. ATEX-approved ionisation bars neutralise charges on both sides of the web, reducing fire hazards. Efficiency and contamination levels can be monitored via the Manager IQ or Smart SLC. If performance drops below a set threshold, the PLC or operator receives an alert for maintenance. During drying, temperature changes can cause recharging, so 24V ionisation bars are installed here and before lamination to prevent static from being trapped between layers.

At the final winder, pressure rollers can create high static again, causing shocks to operators. Because the distance to the material changes during winding, a ThunderION IQ is used for effective discharge. For advanced safety and control, the IQ Easy System with inline measurement and CLFB can be integrated with the coating line PLC via Fieldbus. Alarm levels warn operators if static reaches dangerous limits, while data logging supports quality reporting.

This comprehensive approach ensures maximum safety for personnel and minimises the risk of fires in coating operations.

Flexoprint Machine

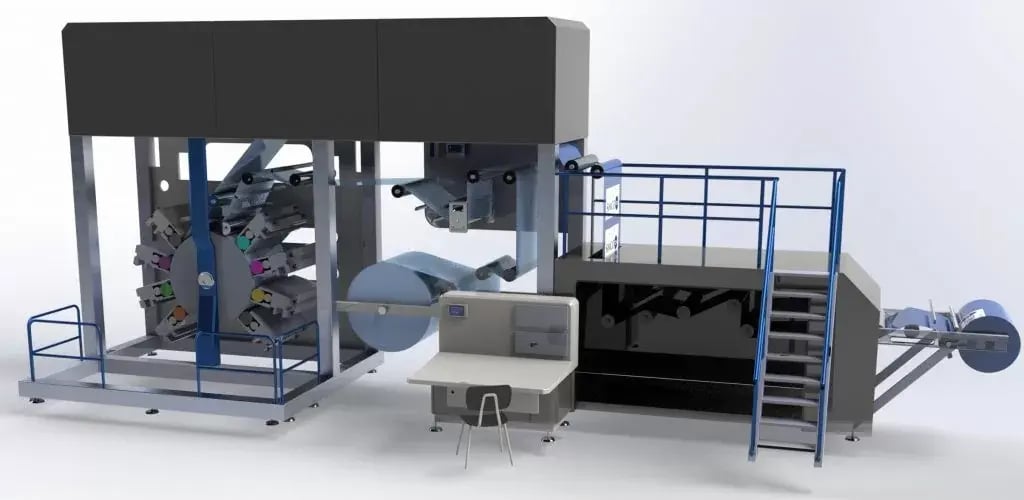

Complete Static Control for Flexographic Printing Machines

Flexographic printing lines, along with other presses, are designed to produce flexible packaging in multiple colours and finishes at high speeds. Static electricity can often be identified by shocks or visible sparks during discharge, but it also causes printing defects such as:

- Ink mist

- Ghosting

- Blurred or fuzzy prints

- Particles on the printed surface

- Dust attraction

- Print imperfections

- Overspray

All these issues can be linked to high-voltage static charges. Static build-up can occur in several sections of a flexographic press, leading to operational and quality problems.

Web Discharging

Neutralising static on the web immediately after the unwinder prevents dust particles from being attracted to the material. It also ensures operators do not experience shocks when touching or passing the web during production.

Corona Treatment

When the film undergoes corona treatment, the process generates a significant static charge on the material. Discharging after the corona treater is strongly recommended, ideally using a closed-loop feedback system for precise control.

Flexoprinting section

If the flexoprinting section is indicated as EX-area (if solvents are used), static charges from the material can ignite the gas and cause a fire. Neutralising and static measuring just before the material touches the central (printing) drum is advised with our ATEX approved devices like the Sensor IQ Easy EX and our Performax IQ Easy EX. This way, static charges are actively monitored to ensure a safe level, resulting in long and high quality production runs. After the printing section the material might generate static again in the dryer. Placing ionisation bars with a sensor enables neutralising and monitoring of static charges before the film goes to the next section of the machine.

Winding Station

At the winding station, anti-static bars combined with a Sensor bar (in closed-loop feedback) are installed to neutralise the material during winding. This prevents operator shocks during roll changes and avoids telescoping of the finished roll.

By implementing full static control across the flexographic printing process, manufacturers can improve print quality, reduce defects, and ensure safer, more efficient production.

In-line measuring and datalogging of static charge levels during winding can be used in quality reporting. The IQ Easy System can be directly connected to the PLC of the flexoprinting machine via Fieldbus connection. An alarm level alerts the operator in case the static charge reaches a dangerous level. This is how the IQ Easy System provides all essential information to maintain high speed, high quality and competitive flexoprinting.

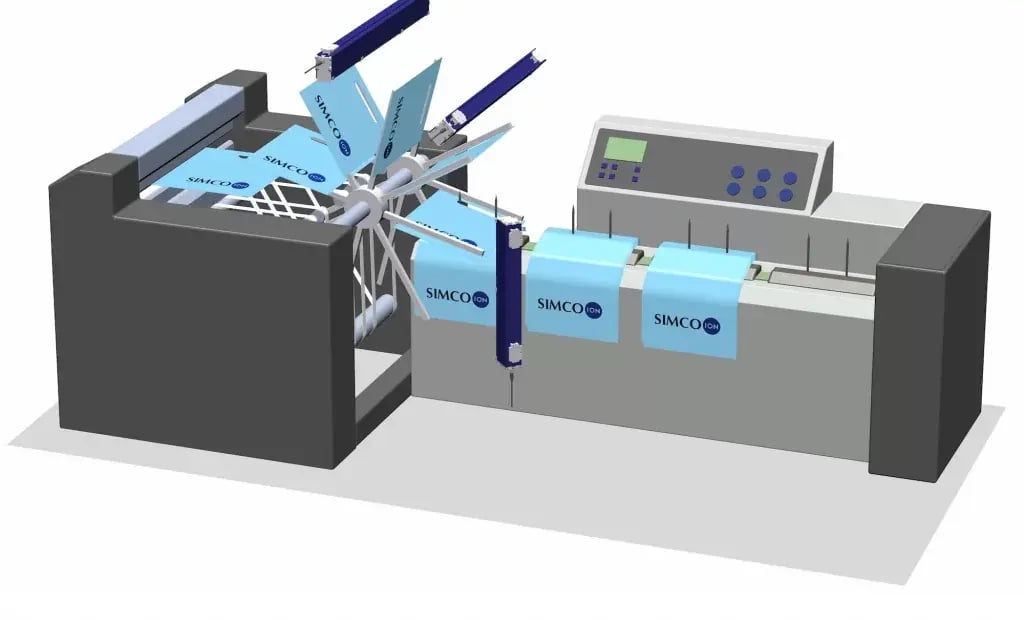

Slitting and Rewinding

Efficient slitting and rewinding – preventing static problems

Slitting and rewinding is a process in which jumbo rolls of varying widths are converted into narrower rolls at very high speeds. This process is suitable for a wide range of materials, such as paper, plastic film, flexible packaging, textiles, and fabrics. The web is unwound, guided through the slitter/rewinder past adjustable knives, and then rewound onto one or more shafts to create narrow rolls.

Although this process is widely used today, the combination of high speeds, friction, and multiple rollers creates a risk of static electricity build-up, which can lead to process disruptions.

To prevent this, 24V Performax (IQ) Easy Speed ionising bars are installed immediately after slitting and before rewinding. These neutralise the accumulated static charge and prevent:

-

New static charge build-up during the rewinding process

-

Attraction of dust and cutting debris

-

Electrostatic shocks to operators

-

Telescoping of slit rolls

If a low static level is required on the finished product, an inline measuring system can be applied. The Simco IQ Easy System provides real-time control and monitoring via a closed-loop feedback (CLFB) system.

This system monitors all ionisation equipment and can be connected to the machine’s PLC via fieldbus. It provides insight into efficiency, maintenance, and static charge levels, including alarms. Inline measurement and data logging of electrostatic values support quality reporting.

This approach ensures improved static control, enhances safety, and guarantees high product quality, resulting in an efficient and competitive slitting and rewinding process.

Bag Making

Static electricity in bagmaking machinery: Challenge and opportunity

Bagmaking machines vary in design depending on the type of bags they produce. These machines create bags by unwinding a roll of plastic film and processing it through operations such as heat sealing, cutting, slitting, and stacking. Common products include garbage bags, T-shirt bags, shopping bags, and draw-tape bags.

Due to the machine’s construction, bagmaking equipment generates significant static electricity. Friction between rollers and the passing plastic film causes electrostatic charges to build up on the material’s surface.

These charges can lead to poor machine performance, misaligned stacks, reduced production efficiency, and increased waste. Such issues are common across bagmaking systems like Bags-on-Roll (interleaf) and Bag-on-Bag (e.g., wicketer machines), which are widely used in industries such as packaging, food, beverage, and medical.

Static elimination solutions

To neutralise electrostatic charges, Simco-ION offers a full range of static control products. Frequently used options include AC static eliminators such as MEB, MaxION, and ½” Super Service bars (heat-resistant Teflon for sealing units). Additionally, 24V static eliminators like Performax IQ Easy (Speed), VicinION, and ThunderION IQ are applied. These long-range discharge bars effectively eliminate charges that cause stacking problems, particularly on wicketer machines.

Using static to improve processes

Interestingly, static electricity is not only a problem—it can also assist production. On bagmaking machines, static is applied to charge rolls (e.g., garbage bags) to prevent air pockets, maintain compact rolls, and stabilise the process. It also helps material adhere to metal rollers without air inclusion, improving cooling efficiency.

Charging the last bag on a roll secures the end, making packing into cartons easier. Static charging can also enhance production control by stabilising folds or aiding transport and stacking within the machine.

The combination of our CM5 and HDR chjarging bar is the perfect solution for generating static in a safe and controlled way to improve your process.

Perforation detection

Controlled sparks are used for perforation detection, enabling non-contact quality inspection and even counting perforations (including for biodegradable bags). This is achieved using Simco-ION high-voltage generators, such as the Simco CM5 or Simco 24V Perfomaster. These generators convert sparks into signals for the machine PLC, providing data on defects, positioning, and production counts.

By combining advanced charging and discharging techniques, Simco-ION ensures high-quality, efficient, and competitive bagmaking.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Rob Achterkamp, Sales Consultant

“In high-speed converting, static can lead to jams and defects. We visit your facility to implement solutions that keep your processes efficient and reliable.”