Style Guide

The perfect template to dial in your theme settings.

Static Elimination

Static Elimination

With Simco-ION products

On this page, you’ll learn about the role of static elimination in industrial processes, the situations where neutralising static electricity is essential, and the Simco-ION solutions designed to meet those needs. From advanced anti-static systems to specialised ionisation products, we provide the tools to keep your operations efficient, your products consistent, and your workplace safe.

Click on the buttons above to jump straight to the associated paragraph

Static Elimination

Static elimination products consist of several different products to eliminate or neutralize static electricity like on film, web or products. There are static eliminator bars, DC long range ionising bars, AC ionising bars, industrial static eliminators. But also air supported products like, ionising guns, air knifes, desktop ionising fans and ionising nozzles. In line ionisers, ionised air blowers, ionising blowers are also part of the program. Furthermore we produce the power supplies to power the different types of ionisers.

Different types of Static eliminators

Static electricity can be troublesome in many production processes where non-conductive materials such as plastic, paper, wood and textile are processed. Especially during the winter months, when outside humidity is low and inside the air is dry, static can cause many problems. In processes like printing or coating, static needs to be eliminated for safety and quality purposes. Static control can be of major importance if production processes work with isolated (non-conductive) materials.

(High) static charges can result in production problems like:

Complete machine stops

Undesirable attraction of dust and particles

Electrical shocks to production employees

There are two ways to remove static electricity: the passive and the active method. If the static has to be removed in a professional and controlled manner, the modern industry is choosing for the active method. Active removal of static electricity is done with high voltage ionisation equipment. This equipment produces positive and/or negative ions to remove static electricity from your products. If your product is negatively static charged it will attract positive ions and when charged positively it will attract negative ions.

Simco-ION Europe has been developing and producing this ionisation equipment for over 60 years now. In our product range you will find : Ionisation-bars (AC and DC), air nozzles, air blowers, air knives and power units.

A static charge remover needs to be used to solve the static electricity problems. There are many different static eliminators produced by Simco-ION Europe differentiated by the different applications, the way to operate or the place where they can be mounted. Please click on the link of the different types to find the right type of static eliminator for your application. Or get in touch, to receive non-binding assistance.

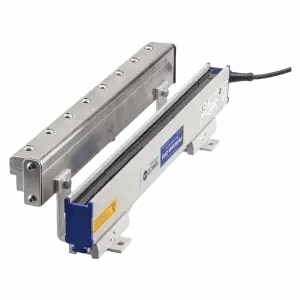

Chosing the right type of industrial static eliminator

Simco-ION anti-static bars or industrial static eliminators generate an electrical field which causes the air molecules in the vicinity of the bar to break down into positive and negative ions. The anti-static bars come in different lengths that vary from 20cm up to more than 5 metres depending on the type. The housing of the static eliminators ranges from very small (24 x 27 mm) up to larger sizes that align with the working distance to the material. There are many different industrial static eliminators, differences between them are found in;

-

How the static eliminator is powered (VAC-230/110/120 or 24Vdc)

-

The distances to the material that needs to be neutralized (short, middle, or long range)

-

Special bars (size of body, special material, ATEX, UL and/or smart IQ bars)

Select how the static eliminator is powered

Static eliminators can be powered by an external power supply that feeds the static eliminator with a high-voltage cable or the bars can be powered with an external 24V DC cable. With the new 24V DC technology solutions, the high-voltage power supply is integrated into the bar. The advantage of 24V is that no high-voltage cables need to be placed in the machine. Below you find the table for selecting the right static eliminator. The 24V DC ionisation bars are shockfree (no shock when touching) while most of the AC ionising bars are not.

In both the 24V DC and the older AC-powered you can choose for short and long range ionisation bars. Smart solutions like inline measuring, feedback compensation, communication to ethernet and clean-bar-indication are only available in the 24V DC selection. For both AC and DC products, we offer UL-certification.

VicinION IQ

Our solution for neutralising electrostatically charged surfaces in compact spaces at short ranges. This bar is equipped with an integrated high-voltage power supply, it does not need an external power unit. Status LED shows the state of the bar. The VicinION IQ is best suited for distances between 5 and 75 mm from the material. This bar is IQ compatible, enabling full static control with our IQ Manager or Smart SLC.

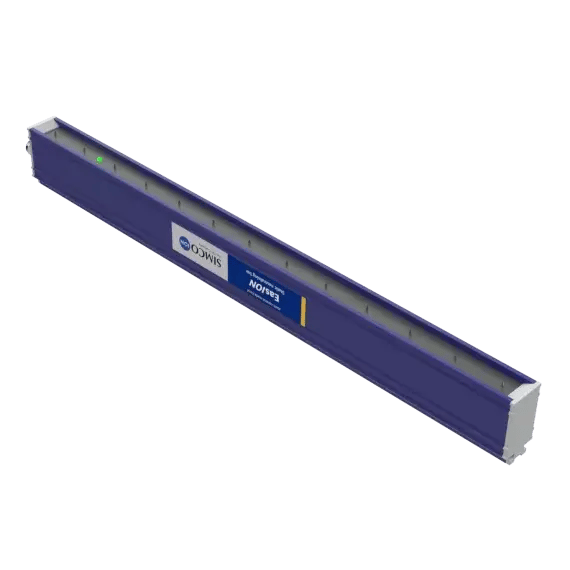

EasION IQ 4.x

As one of our best-selling bars, the EasION IQ 4 offers an excellent solution for neutralising static electricity at medium ranges. Its extensive feature set and IQ compatibility make it a highly versatile option. No power unit needed, integrated 24V DC technology inside.

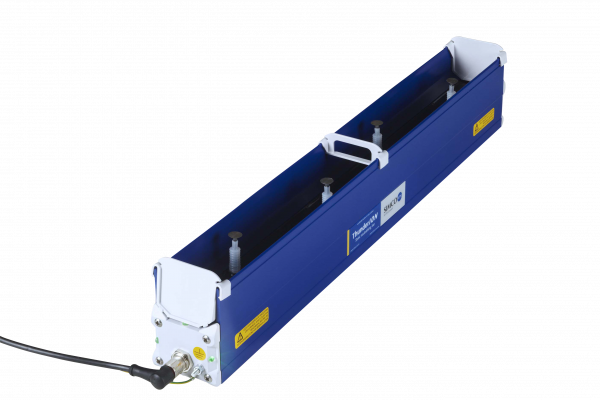

ThunderION IQ

Robust, large, and powerful — the ThunderION IQ is ideal for neutralising static electricity at long ranges. Thanks to our 24V DC technology, no external power unit is required. It features a rich set of functions, an extended warranty, and full IQ compatibility for closed-loop feedback and advanced control options.

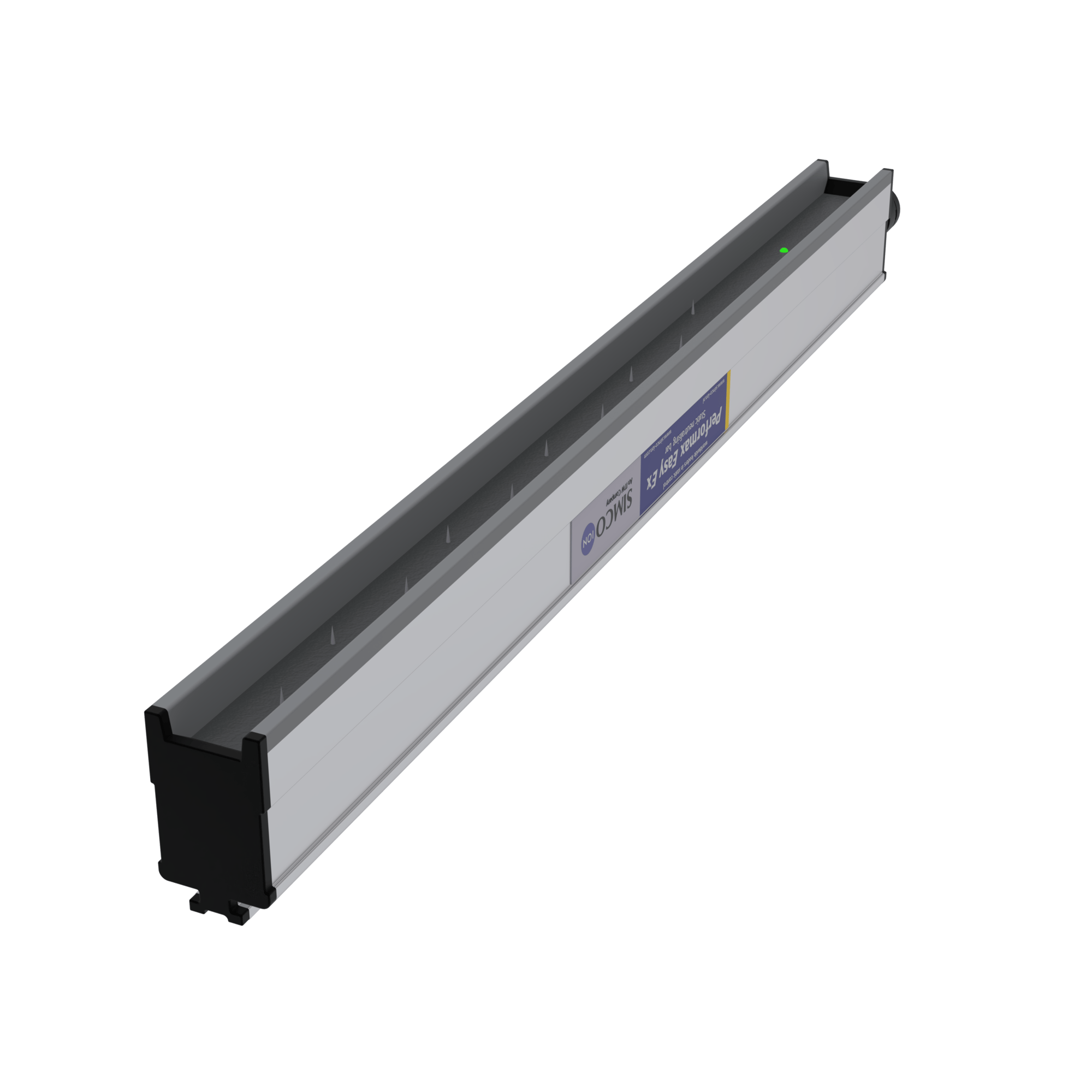

Performax IQ Easy EX

This bar is our smart solution for static neutralising in explosion-hazardous environments. The Performax IQ Easy EX operates at medium ranges and is available in a speed variant as well to handle fast(er) web speeds. IQ compatibility and rich features makes this bar the only one of it's kind on the market.

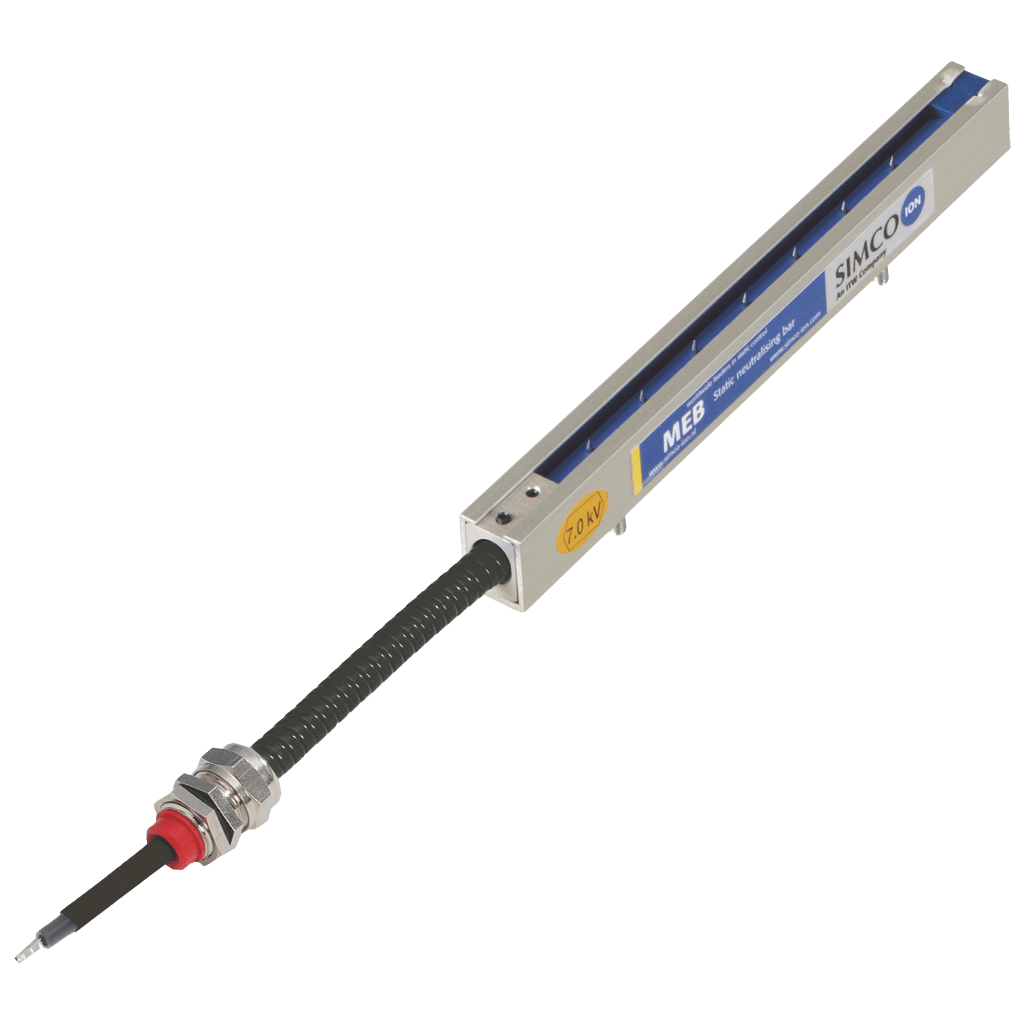

MEB

MEB anti-static bars are often used on production machines were short range ionisation is possible and where no moving machine parts are interfering the ionisation. The properties of this Simco-ION anti-static bar are the same as those of type MEJ, except that the MEJ type is round. An external power unit is needed for this bar

All our other ionising bars:

-

Performax IQ easyMedium range, do it all feature-rich ionisation bar with IQ compatibility. Click HERE for more information.

-

Performax Easy EX

Ionisation bar for explosion-hazardous environments without IQ compatibility. Aimed at medium ranges. Click HERE for more information.

-

P-SH-N-EX

AC ionisation bar that is suitable for explosion-hazardous environments. Integrated power unit, but limited functionalities compared to our IQ products. Click HERE for more information.

-

P-SH-N

Powerful AC ionisation bar suitable for long ranges. Needs an external power unit. Click HERE for more information.

-

EP-SH-N

AC ionisation bar for medium ranges. Requires an external power unit. Keeps working even if several emitters are shorted. Click HERE for more information.

-

Maxion

Medium range AC ionisation bar that needs an external power unit. Fibreglass reinforced casing for reduced chance of bending. Click HERE for more information.

-

MEJ

Internally the same as the above mentioned MEB bar. Features a round body as opposed to the angular body of the MEB. The round shape enables mounting through holes in the machine frame. Click HERE for more information.

-

1/2" SS

AC ionisation bar that is directly coupled to high voltage. Easy to clean, but danger of shocks while the bar is in operation. Click HERE for more information.

Neutralisation and cleaning

Ionising air guns neutralise static charges on materials and clean the surface using ionised compressed air. Neutralising the static charges makes it easier to clean the surface with compressed air, and static elimination prevents dust and dirt particles from being reattracted to the material. The compressed air used for this purpose must be free from oil and water.

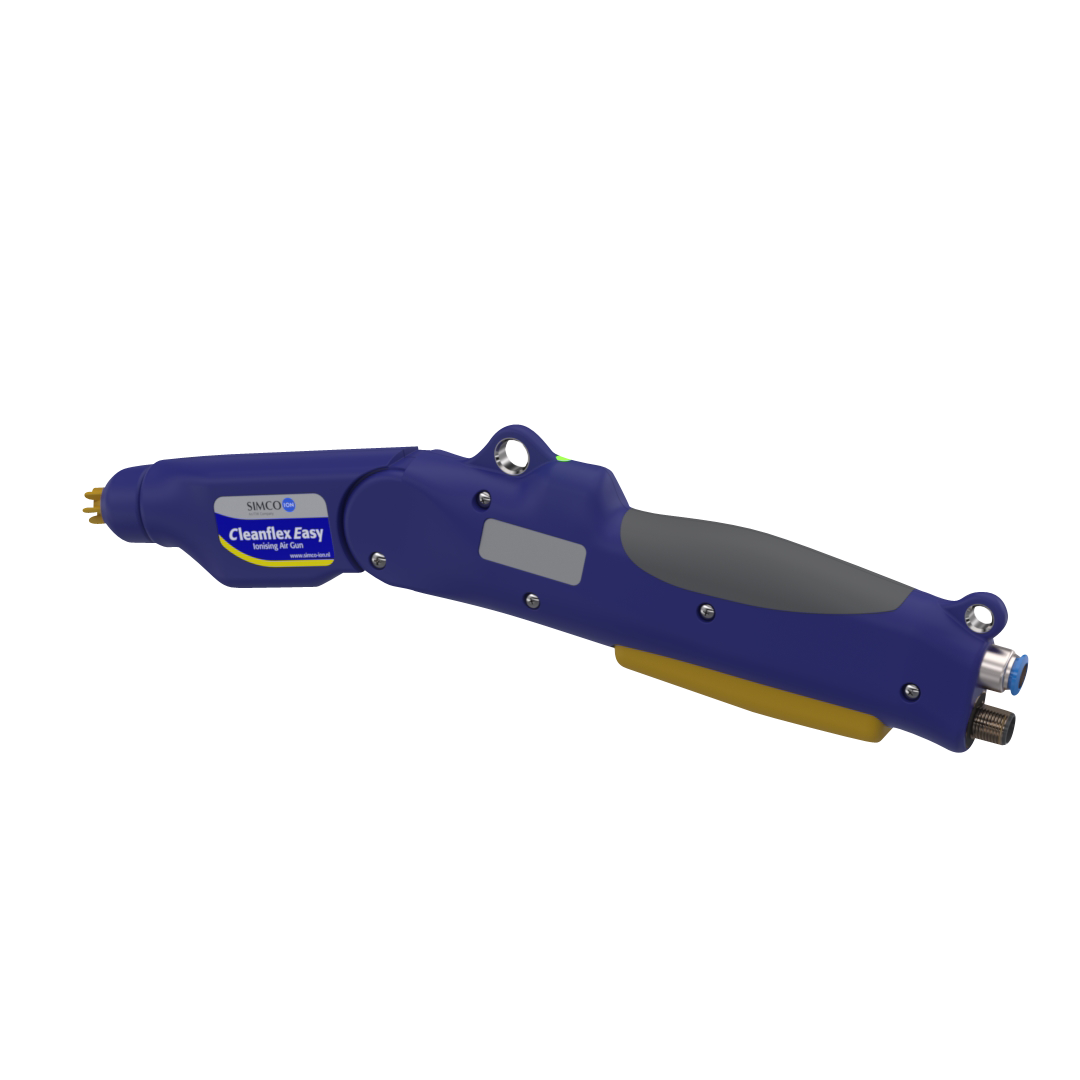

Cleanflex Easy

The Cleanflex Easy ionising air gun can be used for cleaning and neutralising surfaces. Its unique features make it very versatile. The gun can be operated ergonomically, with the entire hand, has a low air consumption and is quiet.

Cobra

The Cobra ionising air gun is suited for heavy-duty industrial applications. It has a lightweight, durable gun body made of high-impact plastic. The airflow is controlled by the trigger. The air flow is amplified by a minimum factor of 6 : 1 by drawing in ambient air through the rear. The high-voltage point integrated aerodynamically in the gun body cleans itself during use. The gun comes standard with 6 metres of cable. A maximum of two guns can be connected to a single power unit.

Top Gun

The Top Gun III provides precise static neutralisation and efficient cleaning for light industrial tasks. Its high ion output, low air use, and built-in air filter ensure clean results. Lightweight and durable, it includes easy-to-use controls, clear status indicators, and electrostatic protection for safe, reliable operation.

Top Gun Sidekick

The Top Gun Sidekick offers handsfree operation. A foot pedal controls both ionisation and airflow. The Top Gun Sidekick includes a mount with a bracket for flexible positioning.

Ionising air nozzles produce a high-velocity ionised air flow which simultaneously cleans the surface, and neutralises static charges on parts and materials. The nozzle uses compressed air and provides an ionised air source for use in cleaning and static neutralising systems. Nozzles can be fitted and installed in many configurations to meet specific requirements, since they are small and easy to install.

Blowflex (IQ) Easy

Our Blowflex Easy is an in-line ionising air nozzle for neutralising and cleaning various surfaces. The nozzle is connected to a 24V DC power supply and incorporates all high voltage parts. The Blowflex is efficient due to a special patented high frequency, high voltage generation. A green LED shows when the Blowflex is in operation. A quick disconnect 8mm hose connection comes as standard. If desired, an ¼” BSP air nipple can be used instead of the quick connect nipple. Mounting positions can be adapted to the situation, using the Simco-ION universal mounting brackets, M8 threaded holes in the bottom, or 6 mm holes in the side. When using the holes in the side, an extra cover plate is provided to complete the housing. The housing is completely IP66, making it suitable for environments where frequent cleaning is conducted. A wide range of output configurations is available to enable efficient ionised air distribution for many applications.

HE

The high voltage at both emitter points of the HE air nozzle is current limited. Being installed outside the air flow, the high-voltage points are hardly subject to fouling. The single point nozzle blowoff force is high at a relatively low air consumption. A Simco-ION power unit delivers the high voltage necessary for operation.

Ionising airblowers

Ionised air blowers are used to neutralise plastic film or three-dimensional plastic products, like injection moulded automotive parts. The main purpose is to prevent dust attraction to the products. Dust particles can stick to the product surface and cause quality problems to the final product. Ionised air blowers are applied to make sure personnel does not receive any unpleasant shocks.

The main advantage of Simco-ION ionised air blowers is that the generated ions are blown directly towards the electrostatically charged product. Emitters create ionised air and integrated ventilators blow the ionised air towards the product. Because the air covers the complete product, ionisation is effective on the complete surface of the product. The air volume can be adjusted on the blowers. Additional air inlet filters can be applied to clean incoming air and ensure optimal ionisation results.

There are different types of Simco-ION ionised air blowers available, depending on required range and operational width. Special ionised air blowers versions for explosion-hazardous environments are available as well.

VolumION

The VolumION is a robust ionising air blower with an effective ionising width of 500 mm. The VolumION consists of a motor, two fans and an ionisation unit. Ambient air is drawn from two sides and blown off along three anti-static bars. The air flow that is drawn in, is adjustable on both sides. This ionising air blower is ideal for long range neutralising when paper and film webs are being wound. The air inlets can be fitted with a special filter.

XC2 Blower

The XC2 Blower is designed for use with sensitive electronic components where electrostatic discharge (ESD) can cause a problem. The XC2 can be used during inspection, testing and in assembly environments. The XC2 can also be used where static electricity causes problems such as; attracting dirt and dust to the product, misalignment of small parts due to electrostatic "jumping", and the undesirable adhesion of plastic films.

HP-N-EX

The HP-N-EX ionising air blower consists of a motor and a fan. The ambient air is drawn from one side and blown off along an anti-static bar. The effective ionising width is 500 mm. This ionisation blower has been approved for use in certain explosion-hazardous environments (ATEX zones). The power unit is integrated in the anti-static bar.

Typhoon

Typhoon blower driven airknives eliminate static and removes particulate from flat or contoured surfaces. Typhoon incorporates a blower with an airknife and can be configured for multiple solutions and industries. This system provides a continuous stream of clean ionised air for removal of surface particulate and contamination.

A Simco-ION anti-static bar with air knife combine the effects of air amplification and ionisation to produce a high-velocity “sheet” of ionised air (amplification ratio as high as 25:1). This combined effect can be used for static neutralising and dust removal in a single operation, for instance in the; automotive finishing, printing, packaging, plastics and textile industries. The air knife is compact and does not have any moving parts. Simco-ION anti-static bars produce an electrical field which causes air molecules to break down into positive and negative ions. These ions are picked up by the high-velocity airflow produced by the air knife and propelled into the work area where they neutralise the charged surface or product.

Air knife with the MEB ionising bar

A type MEB shockproof anti-static bar combined with an air knife comes in standard lengths. The compressed air is blown across the high-voltage points over the entire width and amplified by the ambient air carried along. The airflow is saturated by the positive and negative ions produced by the anti-static bar. The air flow neutralises the static charge, enabling any contamination to be easily blown away.

Air knife with the Performax Easy ionising bar

The air knife with Performax IQ Easy is suitable for situations where the ionisation and cleaning needs to be mobile s.a. cleaning parts with a robot. With the 24V connection an easy installation is ensured. The air knife with Performax IQ Easy is available in 4 lengths; 150, 310, 460 and 610 mm. Longer combinations possible on request.

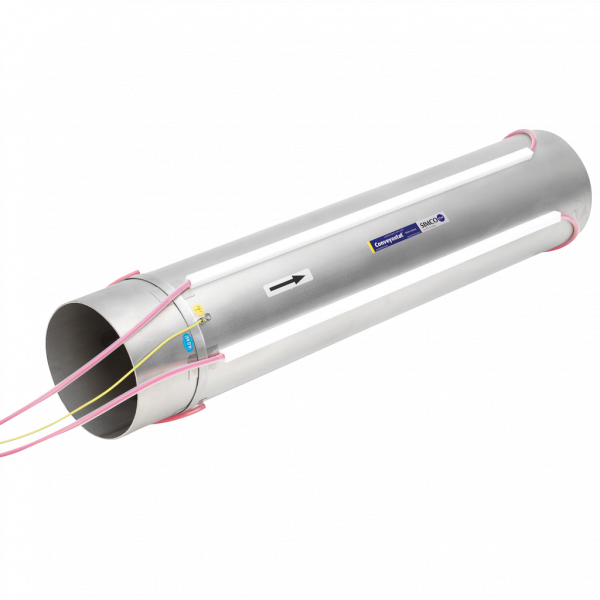

The Conveyostat® has been designed to neutralise static charges on materials in pneumatic conveying systems. In-line ionisation prevents clinging and clogging in tube systems due to static electricity. Production is no longer interrupted because of unclogging, saving precious time. The placing of the Conveyostat® is decided with the Simco-ION consultant, based on the client’s problems.

Conveyostat

The pipe diameter is matched to that of the existing piping system. The number of integrated ionising bars is determined based on the diameter of the tube. We can install the anti-static bars in a pipe provided by the customer as well. The anti-static bars are connected in two groups: They are connected to a two-phase power supply so that optimal ionisation is ensured even at high speeds.

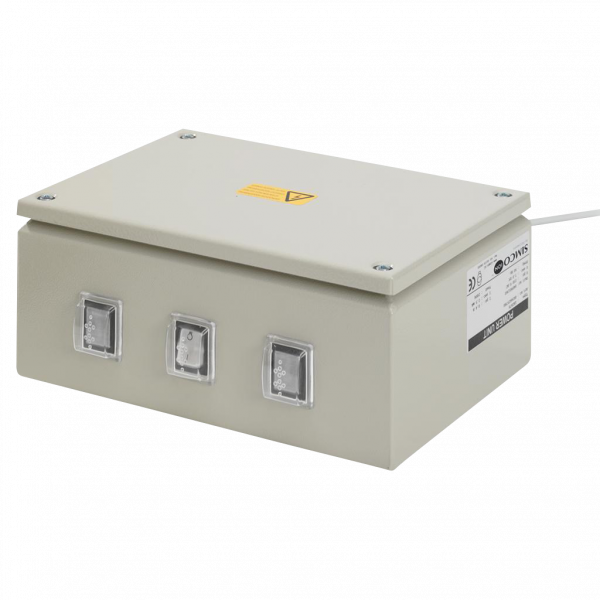

Power Units

Active ionisation equipment operates on high voltage. The power units transform the main voltage to the high voltage required by the ionizer. Connectable main voltages are 110V AC and 230V AC. Connectable frequencies are 50 and/or 60Hz. There are different types of power units available. Power units are easily connected and operated and don’t need any maintenance. Below you find the different types of power units for anti-static equipment produced and delivered by Simco-ION. All anti-static power units can be used as input for the AC static eliminators. All power units have multiple, different output connections depending on the type of power supply chosen.

A Unit

The A Unit has easy-access control and connections. It is equipped with an on/off switch with an indication light as well as a high-voltage indication light. Up to 4 static eliminators can be connected.

LB2A4S

This power unit is equipped with two high-voltage transformers with 180°phase-shifted output voltages. As a result, the anti-static bars connected to the power unit produce positive and negative ions simultaneously. This ensures optimal neutralization of static charges even at very high velocities/speeds. This power unit is fitted with two high-voltage indicators and an on/off switch with an indication light.

MPM

The MultiPowerMaster (MPM) is an comprehensive model with many setting options. It features electronically stabilized output voltage and a wide range of input voltages. Input voltages range from 100 - 240V AC, with a variable 50 - 60Hz option. Output voltage is preset at the factory to 3.3 - 4 - 5 or 7kV. Green and red LED's are incorporated in the top of the MPM. Optionally, the MPM can be fitted with a I/O connector for interfacing with (f.e.) a PLC. Optional I/O signals are available for remote on/off, high voltage indication and overload indication. The I/O connector also contains a 24V power source for use with the Typhoon air pressure sensor.

Pietro Sabatino, Technical Sales

“Simco-ION ensures static elimination is applied where it matters most, improving efficiency and protecting your equipment.”

Typography

You have the ability to have different typography settings for your website and landing pages which is what you see below. You can also control your blog posts typography seperately in the theme settings.

Heading 1

Heading 2

Heading 3

Heading 4

Heading 5

Heading 6

Morbi ultricies, this is a text link nibh quis tincidunt scelerisque, magna purus malesuada erat, feugiat semper urna lectus at sapien. Maecenas ornare, metus ut mattis vehicula, nulla nulla efficitur lacus, vitae congue nisi nibh eget massa. Sed nec pharetra mauris, ac volutpat metus. Praesent sed enim mollis, tincidunt orci sit amet, mattis risus.

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

- Bullet Point

In sit amet massa sed dolor tempor mattis id et tellus.

Icons

You can set a global default color for icons and will also have control in each module to select a specifc color if needed.

CTAs & Standard Buttons

You can set up various button styles to create a visual hierarchy. Pro-top: Make the Primary button pop the most.

Modal Popup

Modals pop-ups are features of various modules. You can give them global style.

Modal Headline

Donec sed pretium mauris. Suspendisse aliquam ornare quam, eleifend sagittis mauris interdum eget. Maecenas placerat mattis velit, in egestas erat vulputate vel. Morbi at nisl justo. Praesent quis erat risus.

Praesent varius quam quis ultricies consequat. Aenean ullamcorper commodo consectetur. Vivamus ex sapien, ullamcorper id ullamcorper in, eleifend in quam. Curabitur ac metus convallis, scelerisque libero in, vulputate justo. Mauris erat ex, commodo vitae ipsum et, vestibulum porttitor odio.

Forms

Create a form that has input fields, dropdowns, checkboxes, and everything. Then style it here.