Pharmaceutical Industry

Discover how you can apply Simco-ION products in your pharmaceutical manufacturing business

Applications for the Pharmaceutical Industry

Processes for medical devices, can be affected by the build-up of static charge. Simco-Ion products are available for many applications, such as injection molding processes, flexible packaging, solution manufacturing, parts assembly and thermoformed packaging.

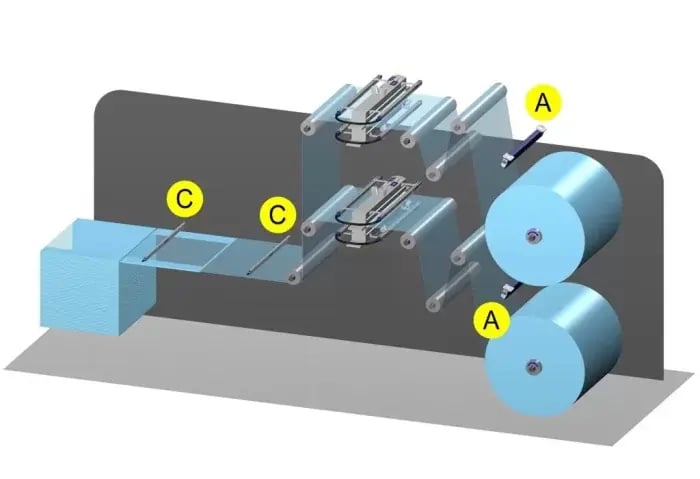

Bloodbag Production

Unwinding a plastic web generates static electricity and the film will be contaminated by attracting ambient dust. Using a Simco-Ion Web Cleaning System removes the dust from the inside of the film, right before the two layers come together and the bloodbag is sealed.

Thermoformed Trays

Within the thermoforming process from film into trays, containers cause high electrostatic charges. These electrostatic charges will attract ambient dust, which contaminates the trays. This may even result in rejects.

When an anti-static bar and webcleaner are installed the static charge will immediately be neutralized and the surface is cleaned. Re-attraction of ambient dust is prevented.

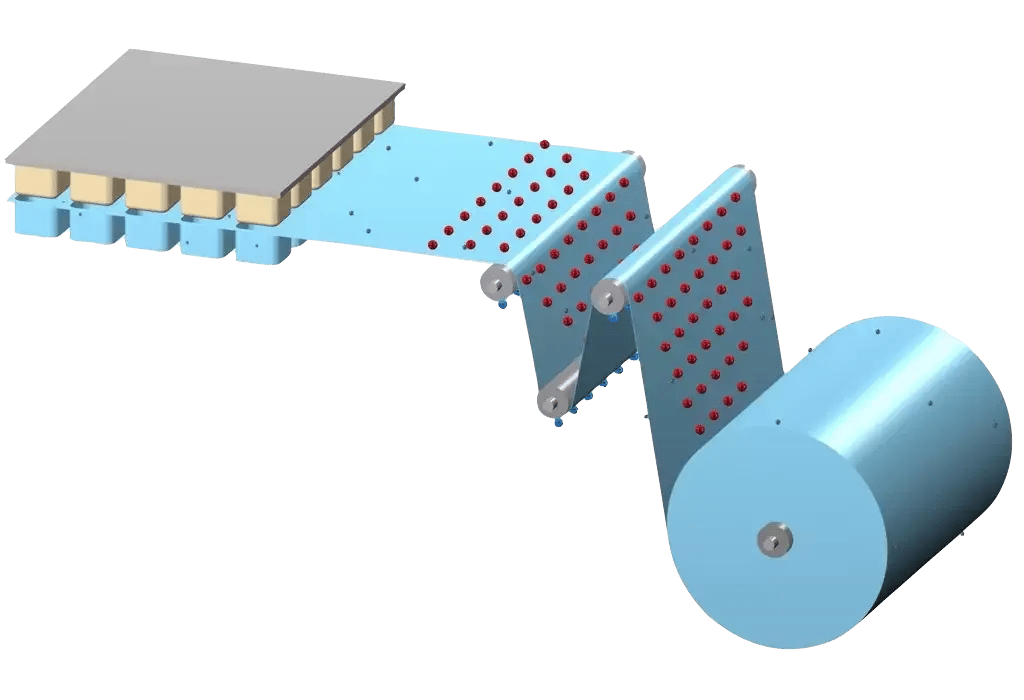

Electrostatical Charging for Medical Filters

Simco-Ion provides electrostatical Generators up to 60kV for the electrostatical charging of non-woven filter materials to reach better filtration results by attracting/bounding the contamination tot the filtermaterial.

Examples:

- Filter material for industrial use (for dust particles and vapor/vapour filtration)

- Filter material for medical use (for mouth masks/caps/lab coats/overalls)

Manufacturers of non-woven filter materials and producers of end-products in this industry are using Simco-Ion high-voltage generators to charge the filtermaterial. The use of electrostatical charging by means of high-voltage-generators at this application servers two purposes:

- To charge the filter material to reach better filtration results by attracting/bounding the contamination to the material when used at the end-user

- To bound (orientate) several layers and materials together, to reach higher production speeds, so higher machinery outputs

How?

For this application the CM5-30 high voltage charging generator, in combination with the HDR charging bar is a proven solution. With out Manager IQ or Smart SLC you can even have Closed-Loop Feedback Charging. The use of mentioned charging equipment increases the output from the machine and the filtration quality from the product so results in high quality competitive filter production.

Vibration Bowl Feeders

Vibration bowl feeders are designed to feed individual components/parts for assembly on industrial production lines. They are used when a randomly sorted bulk package of small components must be fed (in a particular direction) into another machine one-by-one. Vibration bowl feeders come in many shapes and sizes and can be used in the pharmaceutical, food, automotive, electronics and packaging industries.

Electrostatic charges on components/parts are created, not only by the friction and separation between the parts, but also by the friction between the parts and the vibration bowl feeder. Electrostatic charges cause major problems because parts stick each other, to the bowl or even jam the accumulation track. Additionally dust attraction, by the electrostatic charged componentsor parts, can result in quality problems and rejects.

Placing a Performax IQ Easy ionisation bar over the bowl will solve these static issues. Optionally air assist can be required to blow ionised air between charged parts, in order to separate them and prevent misfeeding. Similar technology is applied in the pharmaceutical industry to direct tablets in the right position for transporting to filling-, packing- or inspecting lines. Neutralising with an industrial static eliminator will separate the tablets, ensuring optimal process control and creating a more efficient production.

As vibration bowl feeders come in many shapes and sizes, handle various components/parts, Simco-Ion advises a customised anti-static solution. Optional ionised air nozzles are very suitable to separate electrostatically charged parts. Correct placement of anti-static equipment is crucial, as vibration bowl feeders have quite some moving parts and metal objects that can complicate correct neutralisation of electrostatic charges. Our anti-static solutions make sure that a vibratory bowl feeder is feeding parts in synchronised speed with the production line, preventing expensive production stops.

Simco-ION for your industry

Are you interested in learning more about how Simco-ION products are used across different industries? Browse the industries below for more insights, and feel free to contact us with any questions regarding our applications.

Freek Adolfsen, Territory Manager

“Powder handling, capsule filling, blister packaging—static affects it all. We come to your site, assess the problem, and provide solutions that fit your operation.”